3D Modeling is the basis for our

engineering. That is the only place where productivity is paramount.

You can have all the PLM/MBE gurus debating data management, but it

does not add one smidgeon of productivity to the design process.

Top down or In-Context modeling is

the most productive feature of 3D CAD. Most systems tout this but

each part is still an external part. We are talking about a single

model of multi-object design environment. Both of the systems we

represent offer this as the "normal" design process. Thereby

increasing your productivity 20 to 30%.

In these exercises I not only focus on modeling techniques, but

also on much more productive systems to do our designs. I hope you

enjoy them and learn something. If you are in management, understand

that all 3D CAD systems are not the same. Cutting your engineering

costs is very simple. Even your legacy data is not a problem. Please

feel free to give me a call. There are millions of man hours wasted

every day with poor modeling techniques and ineffective 3D CAD

systems that cost a fortune. Productive 3D CAD systems do not have

to be expensive.

Joe Brouwer

206-842-0360

I am

doing the below assembly for an exercise showing my modeling

techniques and, of course, our superior 3D CAD

solutions.

3D CAD Modeling Techniques

I saw the following video challenges on linkedin

and thought I would give it a try on ZW3D.

These exercises have become incredibly

popular and I have follow up by showing more examples of

this 3D modeling technique!

ZW3D vs Fusion 360

ZW3D vs Solidworks

ZW3D vs Creo

ZW3D vs NX

ZW3D vs CATIA

ZW3D vs Inventor

These exercises started out to show the benefits of

ZW3D over these systems, but

quickly turned into a study of modeling techniques. Take a look at a few of

them, they will open your eyes to a much different and more productive way of

modeling. It really has more to do with modeling technique than it has to do

with the 3D CAD systems. I have found that I do 3D modeling as compared to

the conventional tedious and time consuming constrained 2D sketching. Of course, having a more productive 3D CAD

system doesn't hurt.

ZW3D, being a

sketch based program is very similar to the Pro/e

clones. It is very easy for those users

to get up and running with ZW3D. It has a few operation that

are a bit more streamlined. The benefits over the other systems

are the multi-object environment (top down design) with the integrated drawing. You can

do parts, assemblies and drawings in one file. It also offers

designing with primitive shapes, this alone is a 10 to 20% increase

in productivity over constrained sketching.

These exercises have become incredibly

popular and I have follow up by showing more examples of

this 3D modeling technique!

We will be doing a

couple of parts each weekend in both IronCAD and ZW3D. I hope you

enjoy these exercises and hopefully they may lead to increasing your

productivity.

Please review lessons:

3D Modeling Techniques ZW3D Lesson One

3D Modeling Techniques ZW3D Lesson Two

3D Modeling Techniques ZW3D Lesson Three

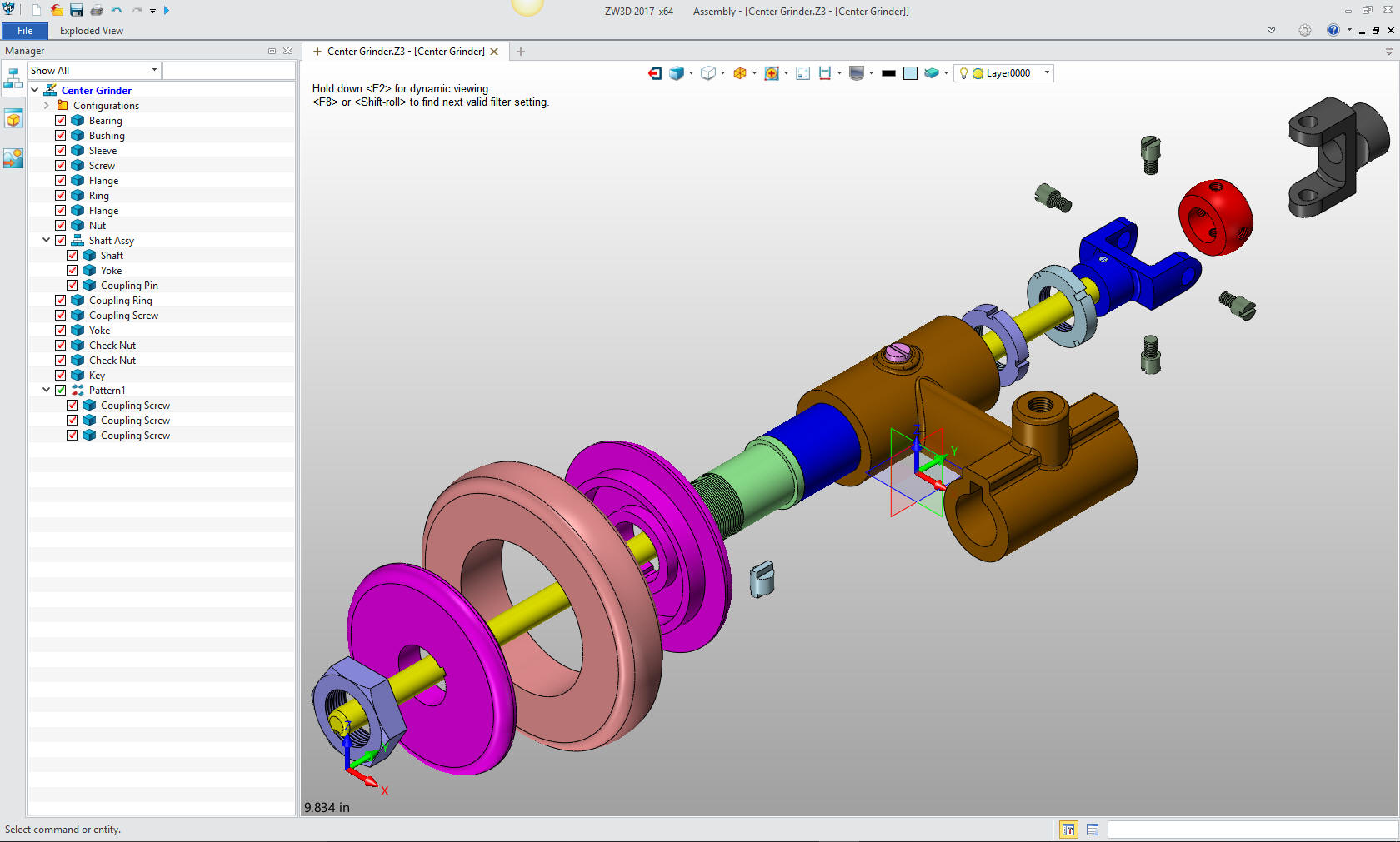

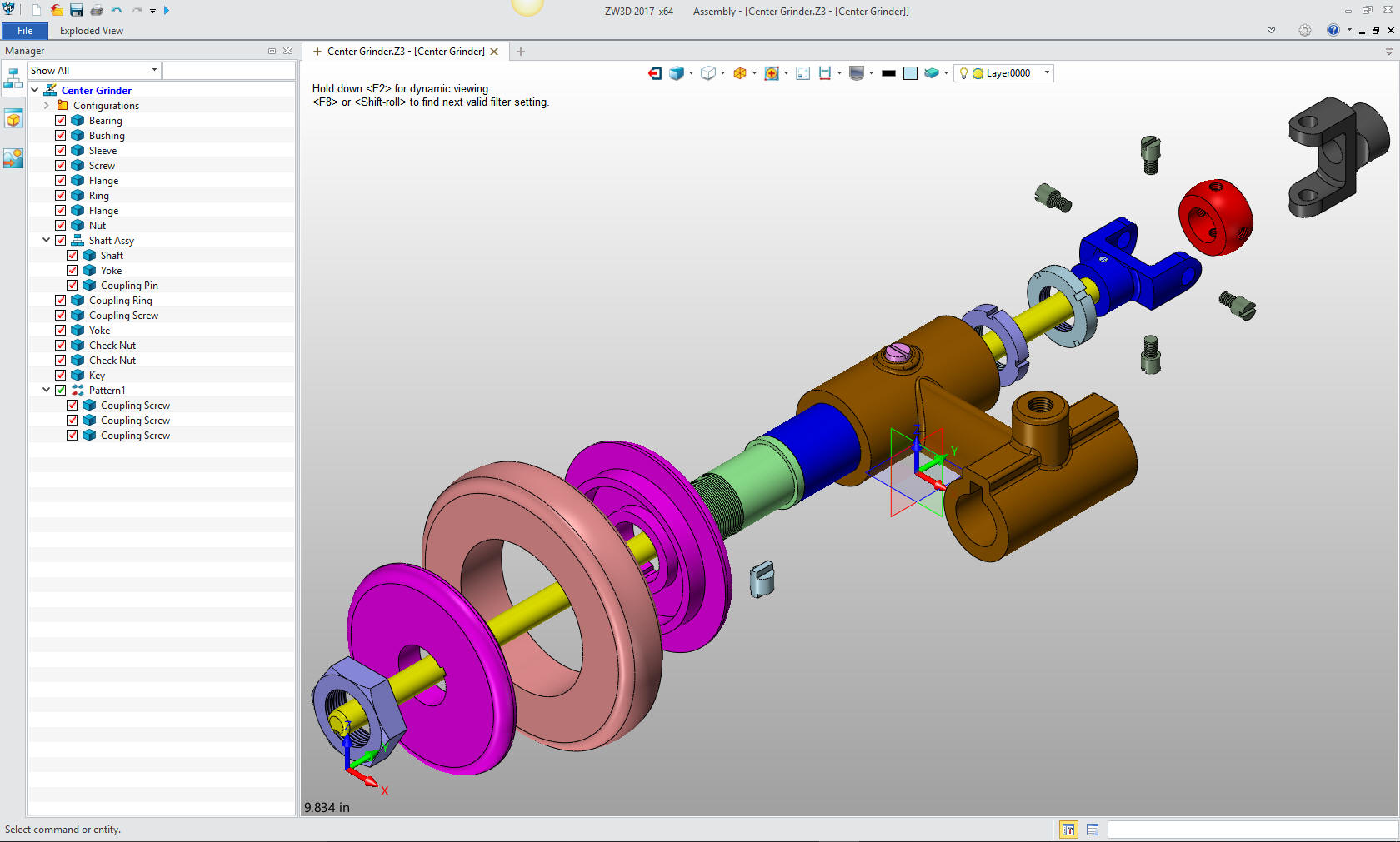

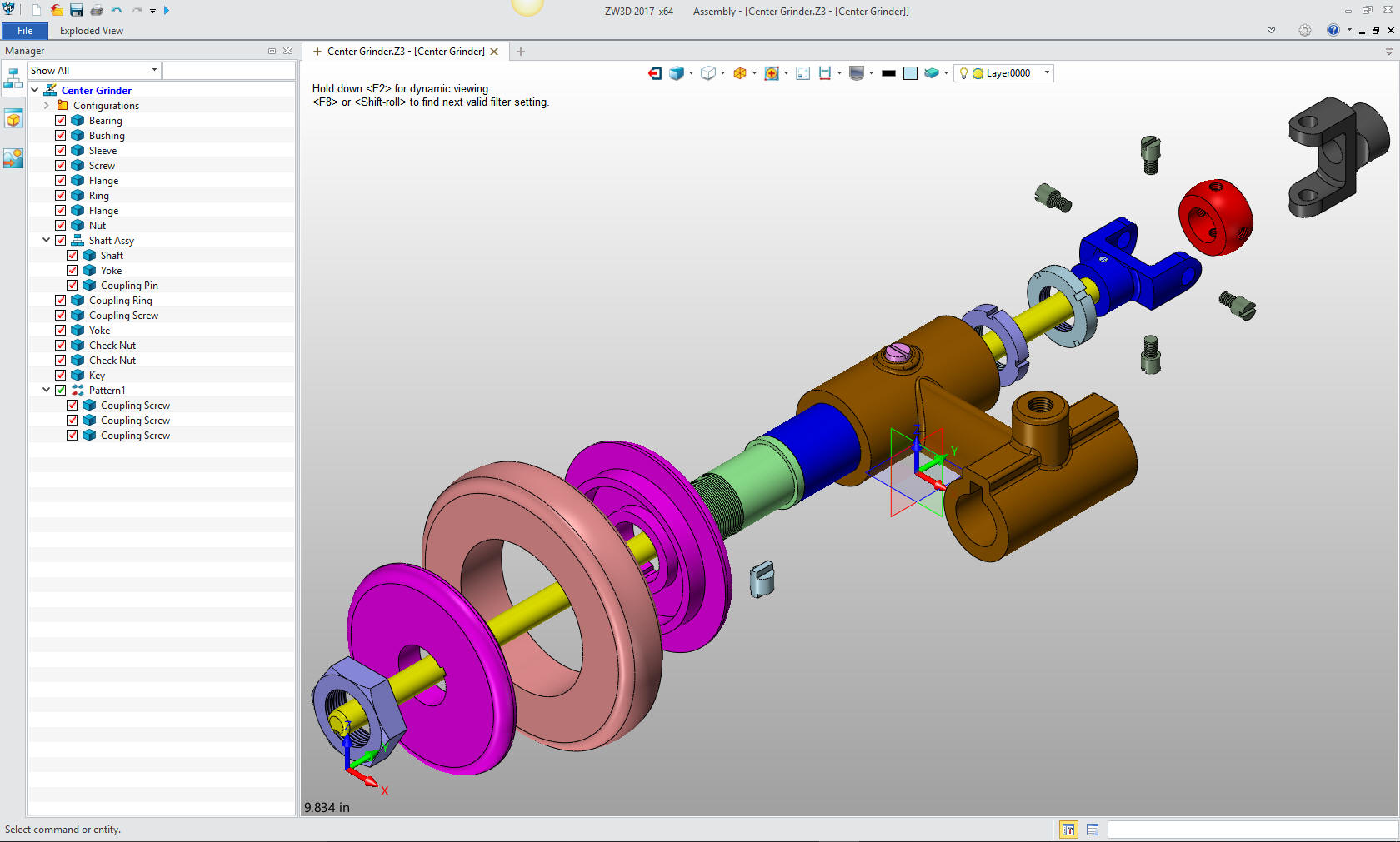

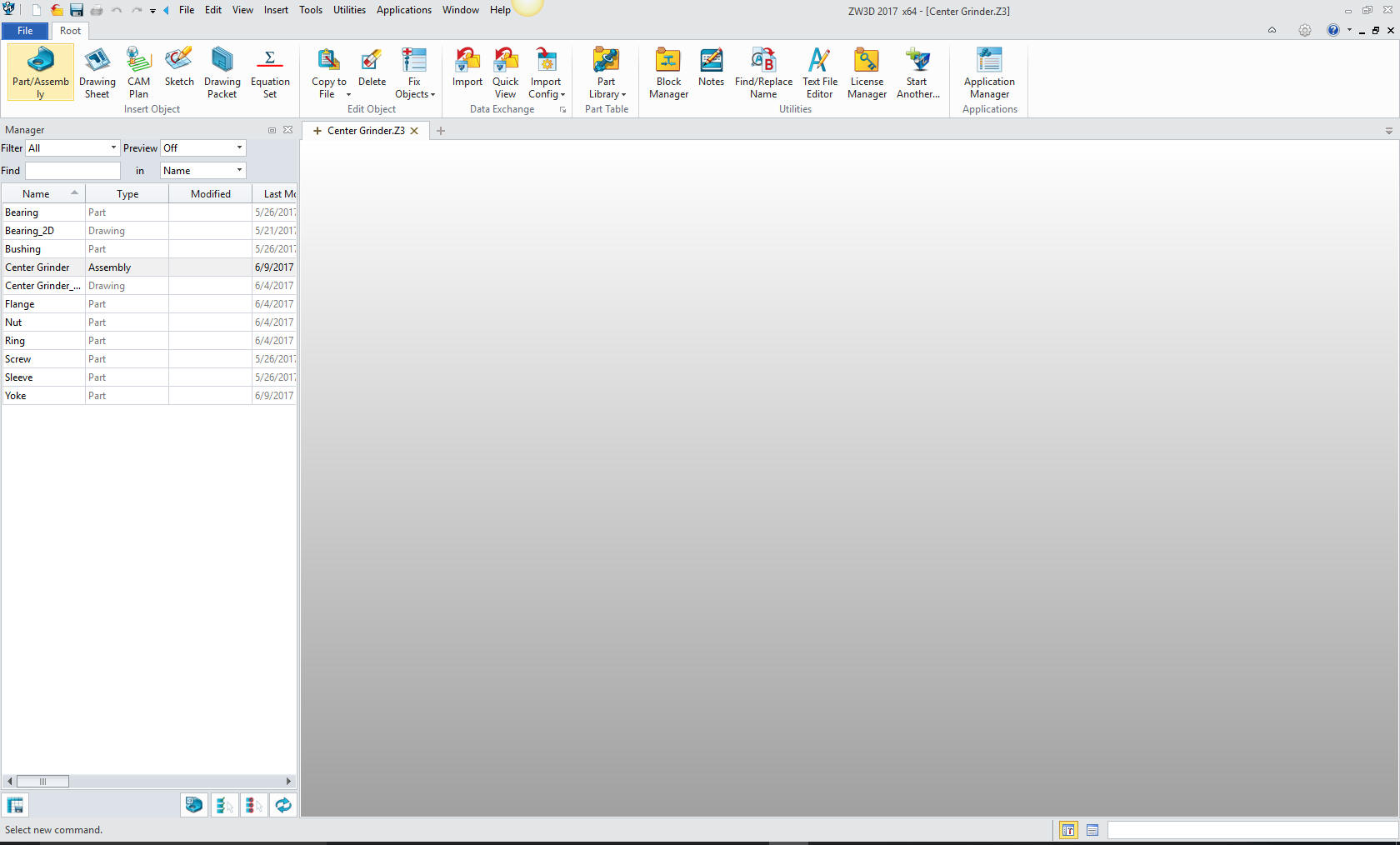

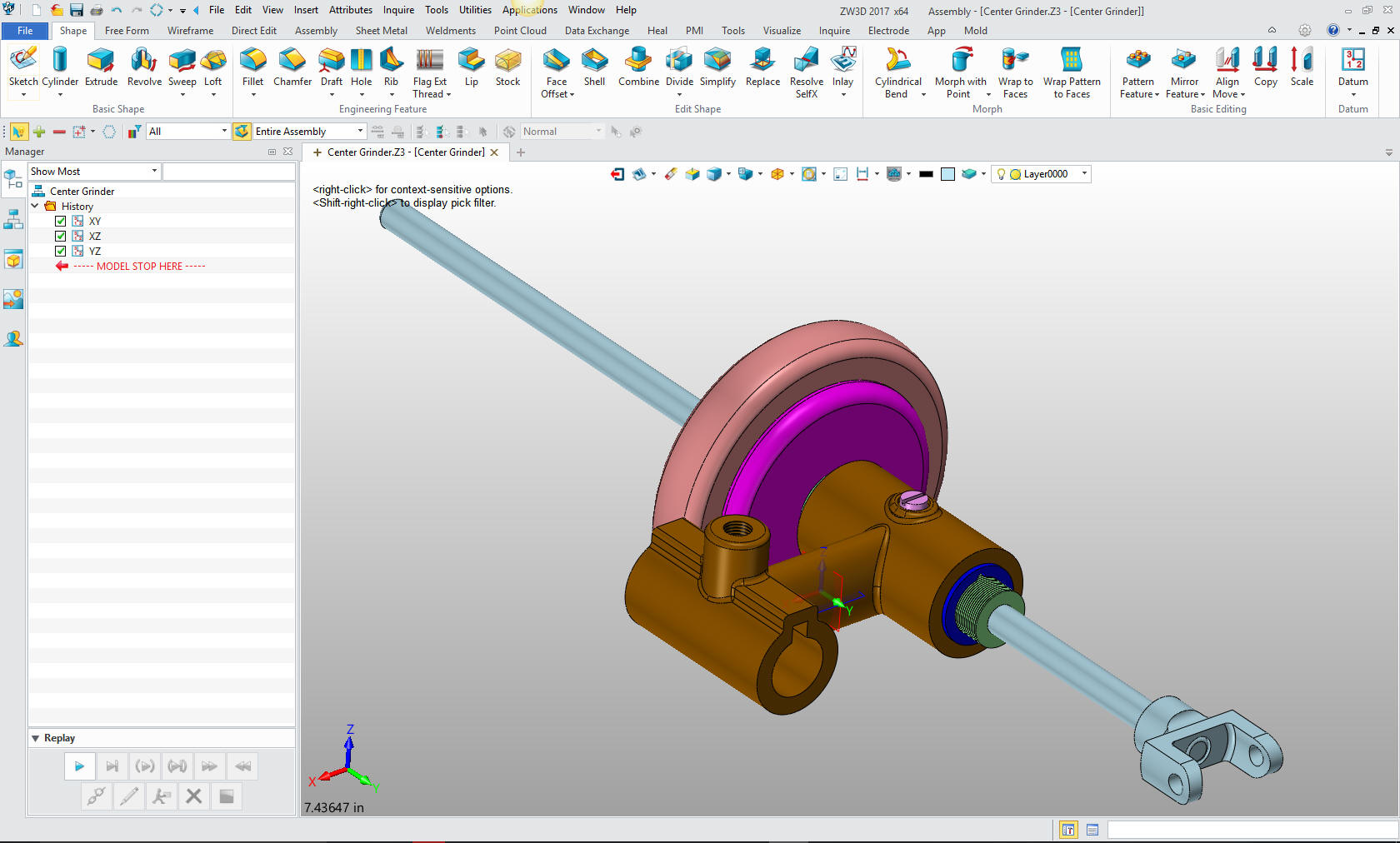

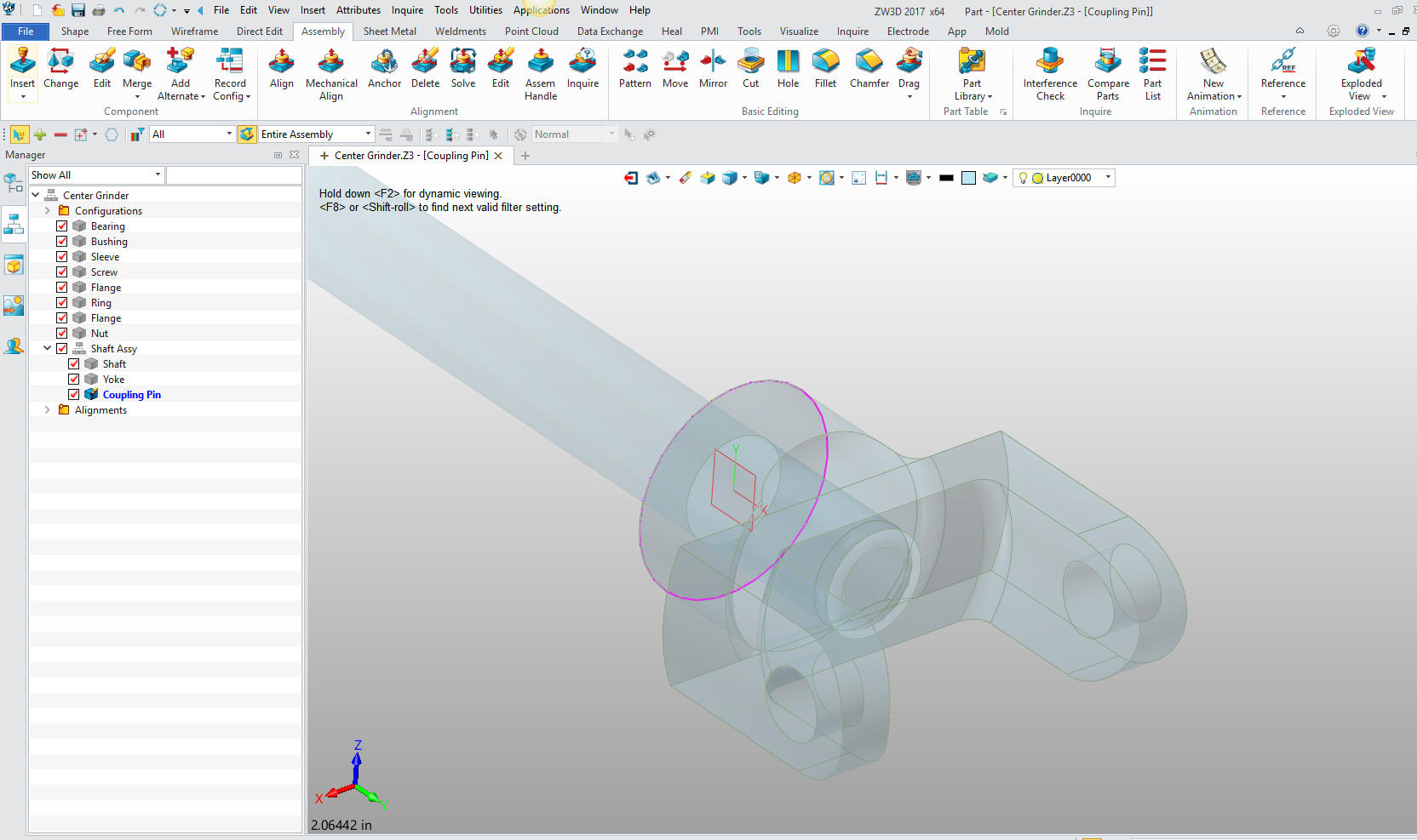

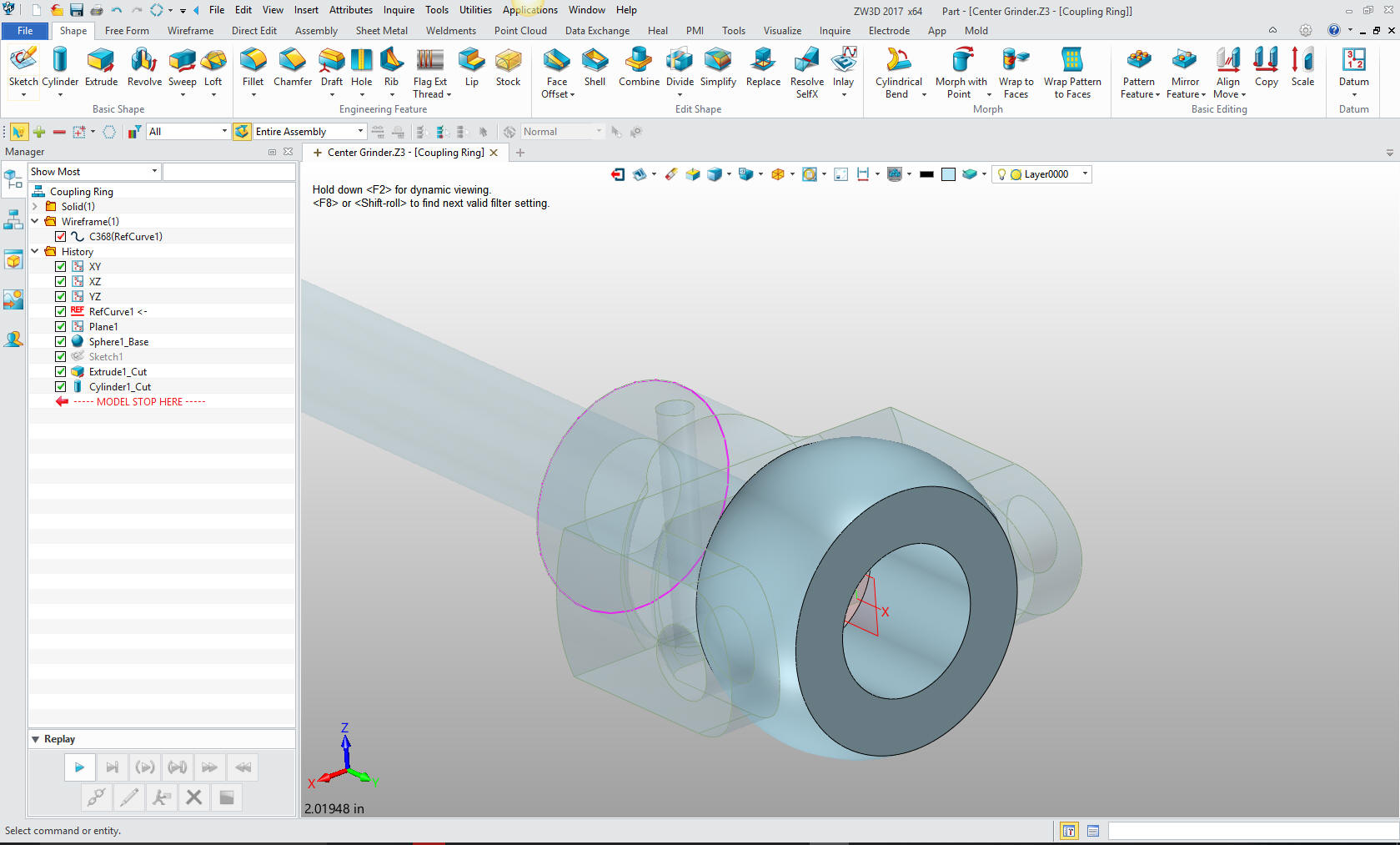

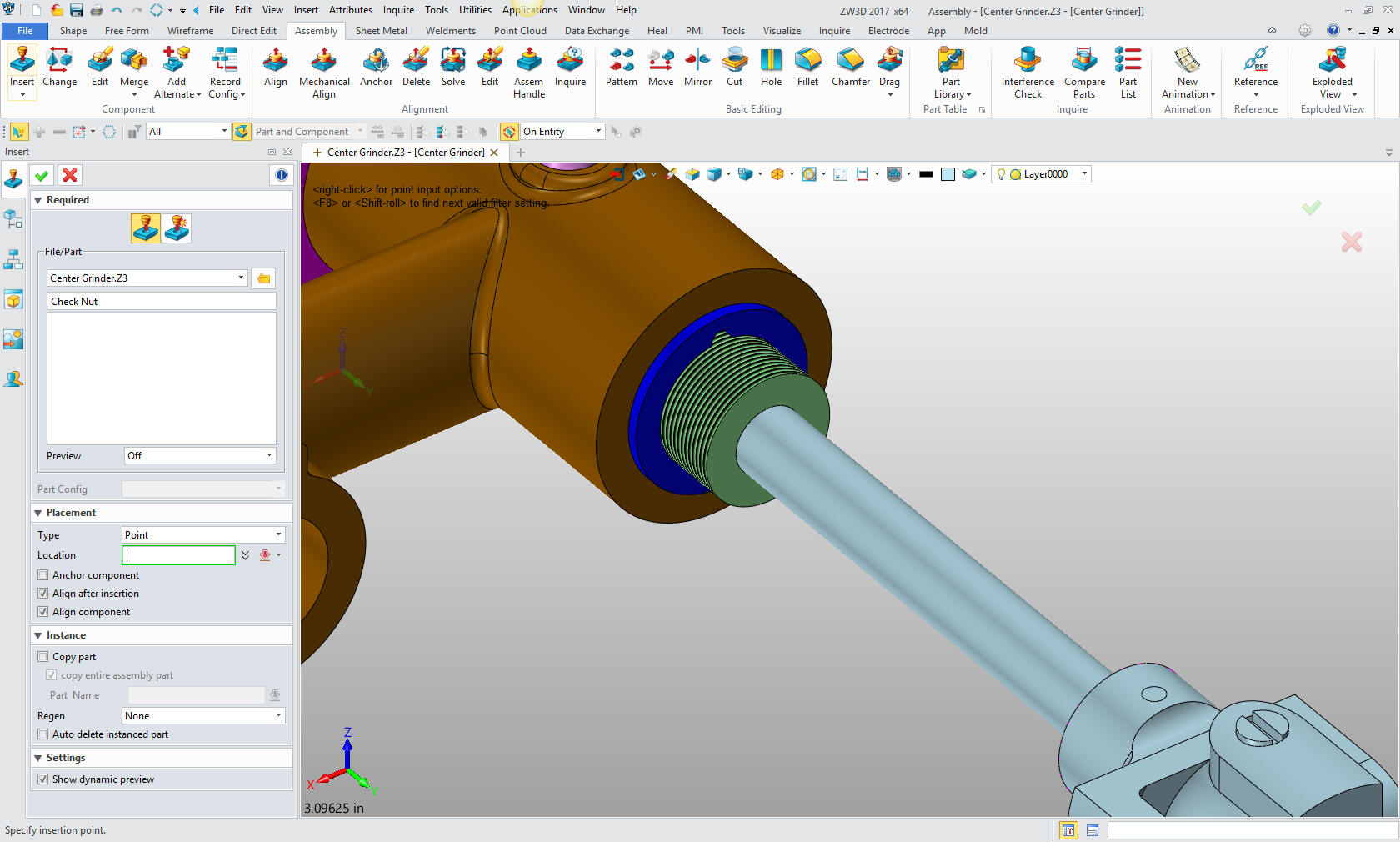

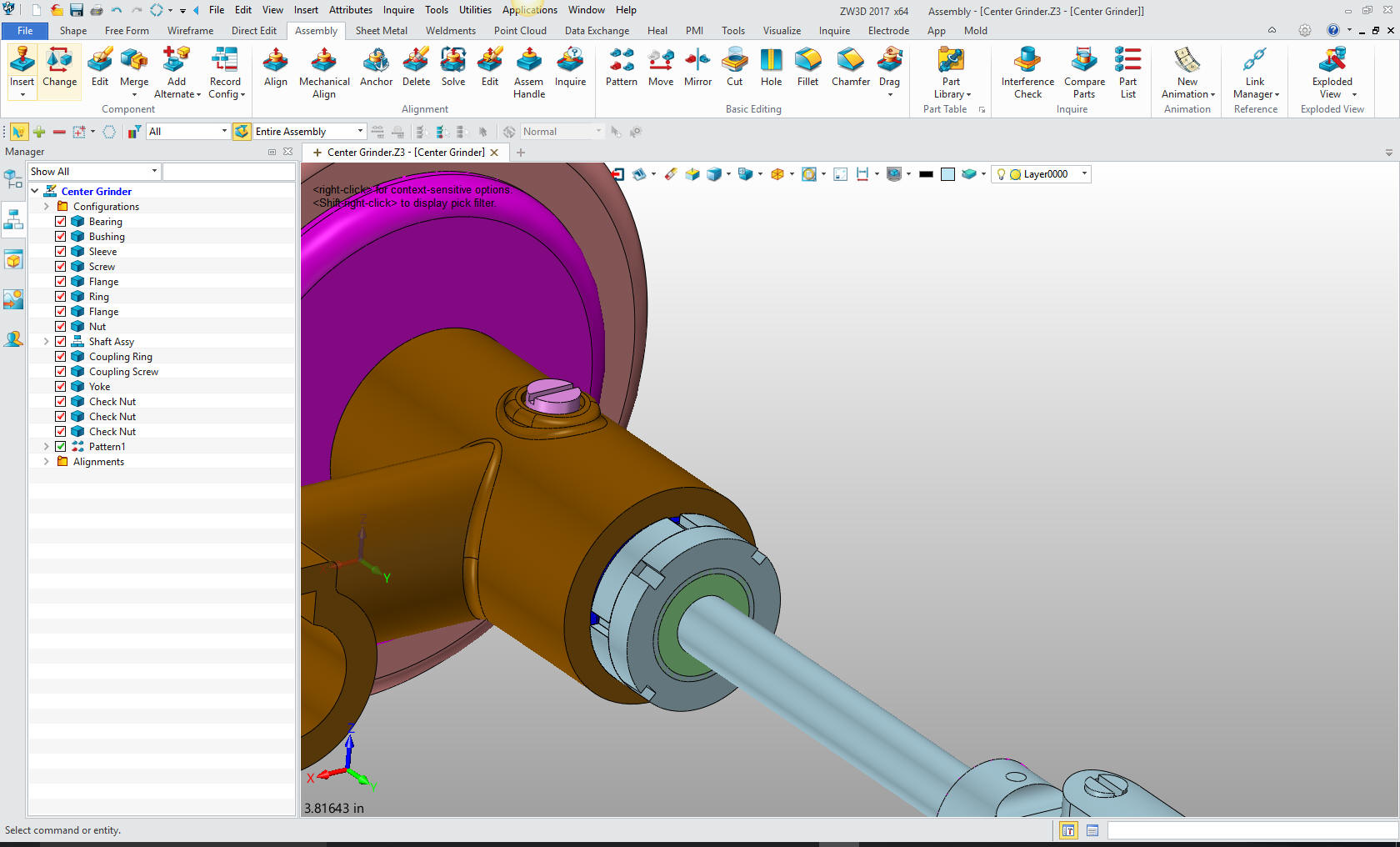

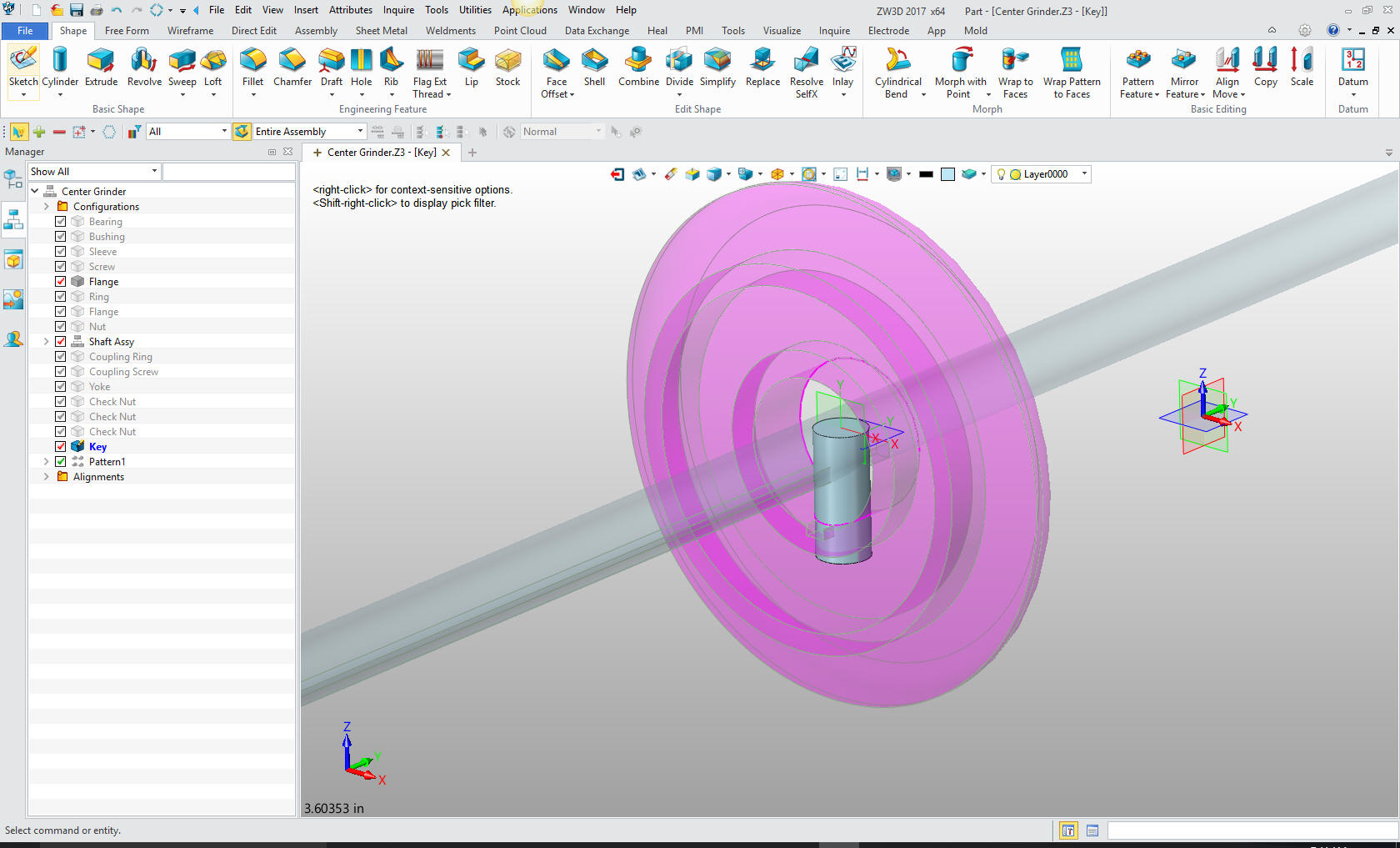

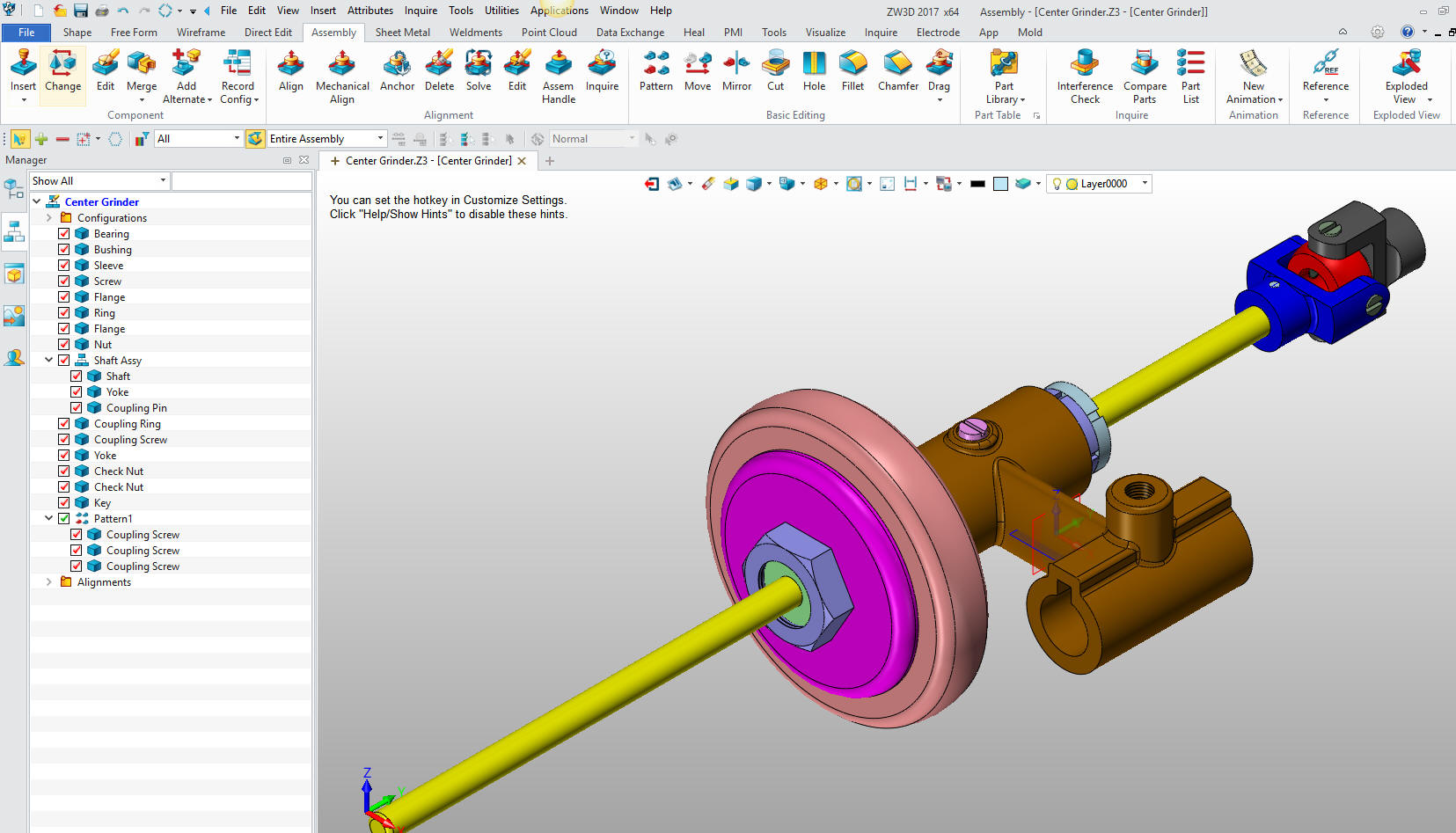

We will bring up the Center Grinder file:

Since we created this file as a multi-object the ZW3D Manager

automatically comes up. It shows the assembly and all the component

parts to this point.

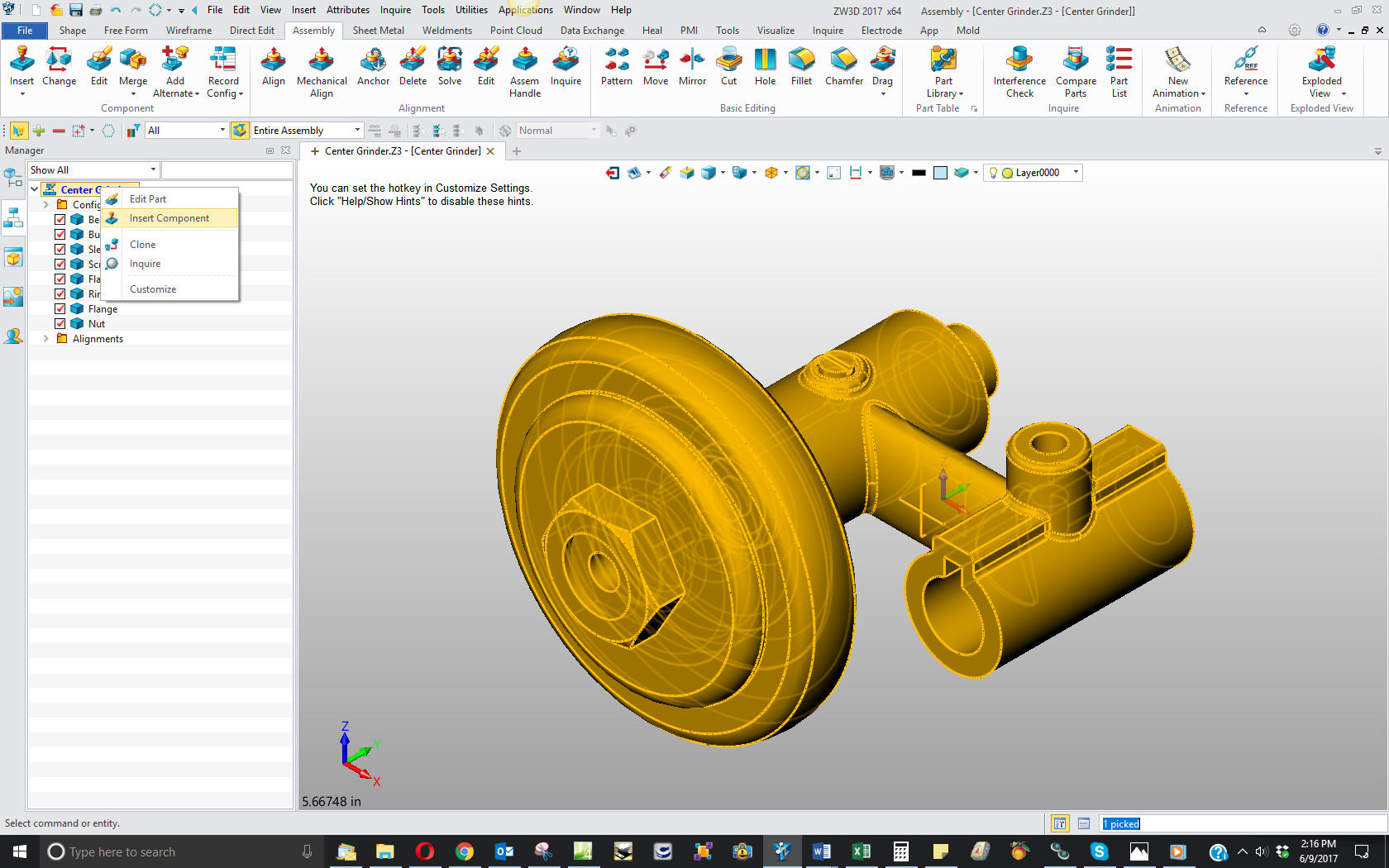

We will select the

center grinder assembly and we will see the existing parts. We will

right click on the Center Grinder assembly and select "insert

component". Again I want to reiterate this is not a true single

model environment. Each part is still like a external reference

except that it resides in the same file.

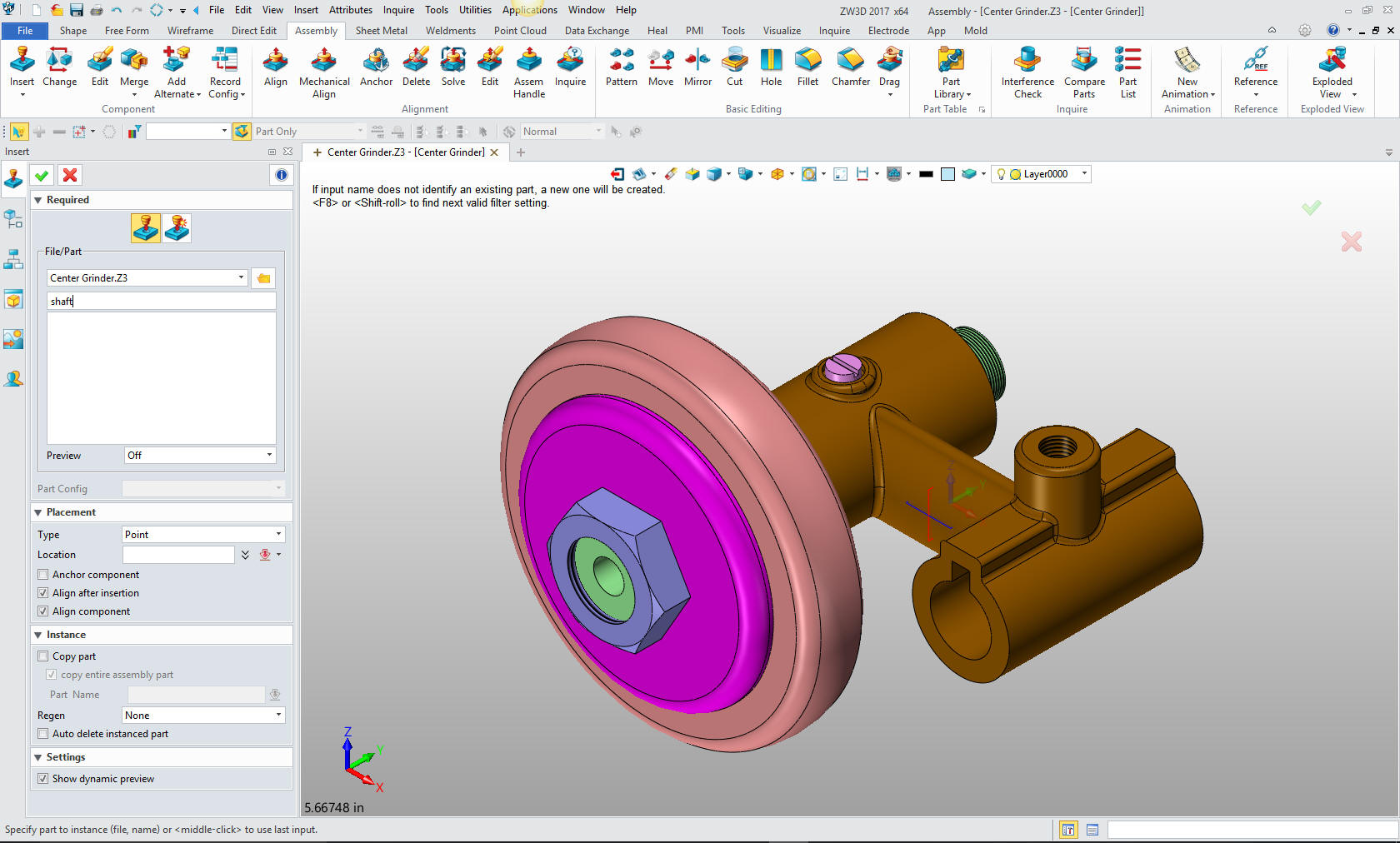

Now we

insert the Shaft as a new part.

Note: ZW3D's Multi-Object

top down design is an incredible time saver. Especially for the

individual design. Which is most of us. Even in large companies a

designer is given a sub-assembly to develop.

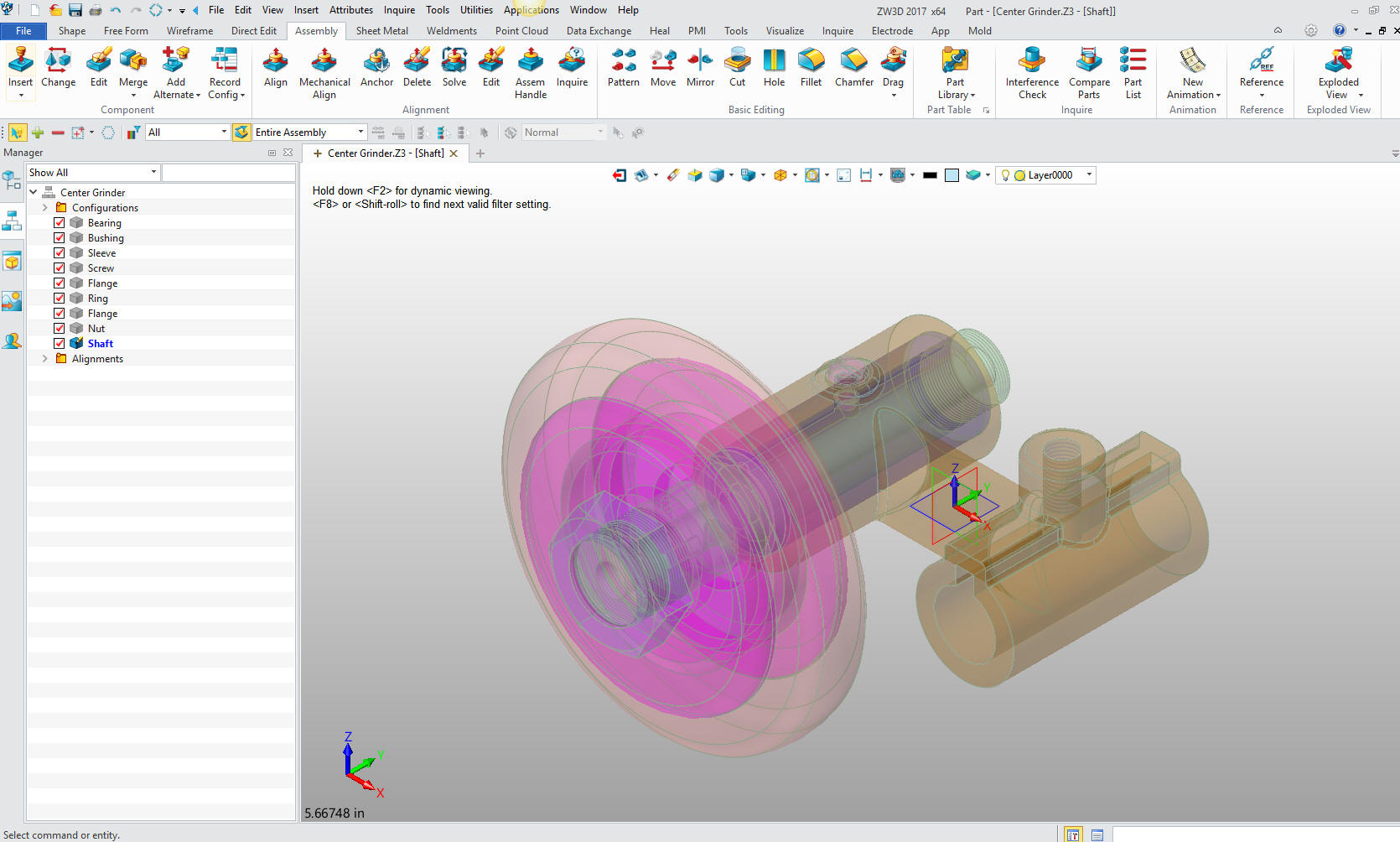

This

step automatically puts us in the "edit part" mode that shows the

other parts as ghosted. They are available for reference as you

will see. We also have the "open part" mode which has only the

single part available. You can make these external individual parts

as required.

Note: I have surprisingly found that ZW3D is a

superior top down design program. I have worked with many top down

design packages (There are only 4 that I know of) and ZW3D is

incredibly productive.

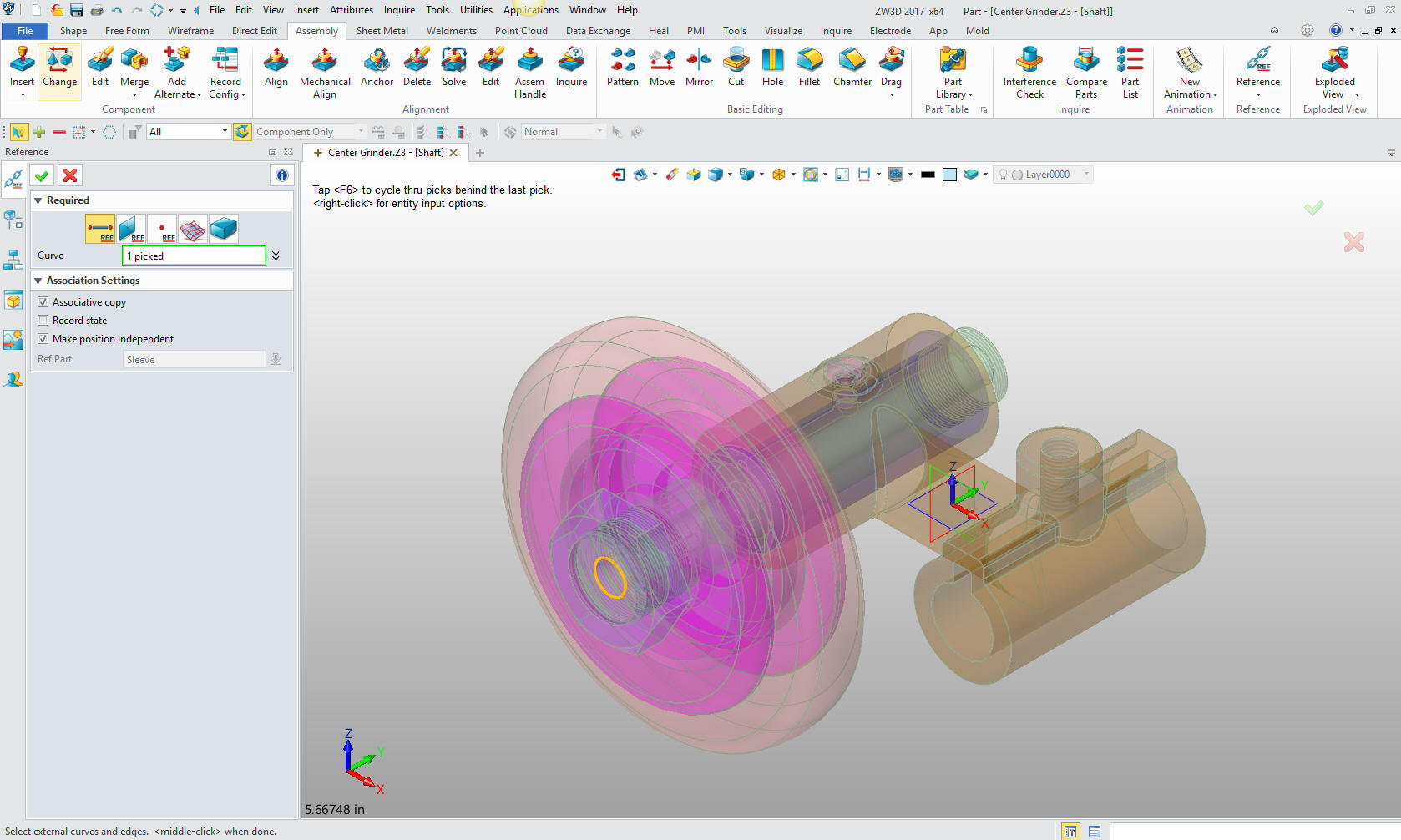

Now

will will begin on modeling the shaft. We are going to design in

top down or in context design. We will go to the assembly menu and

reference an edge.

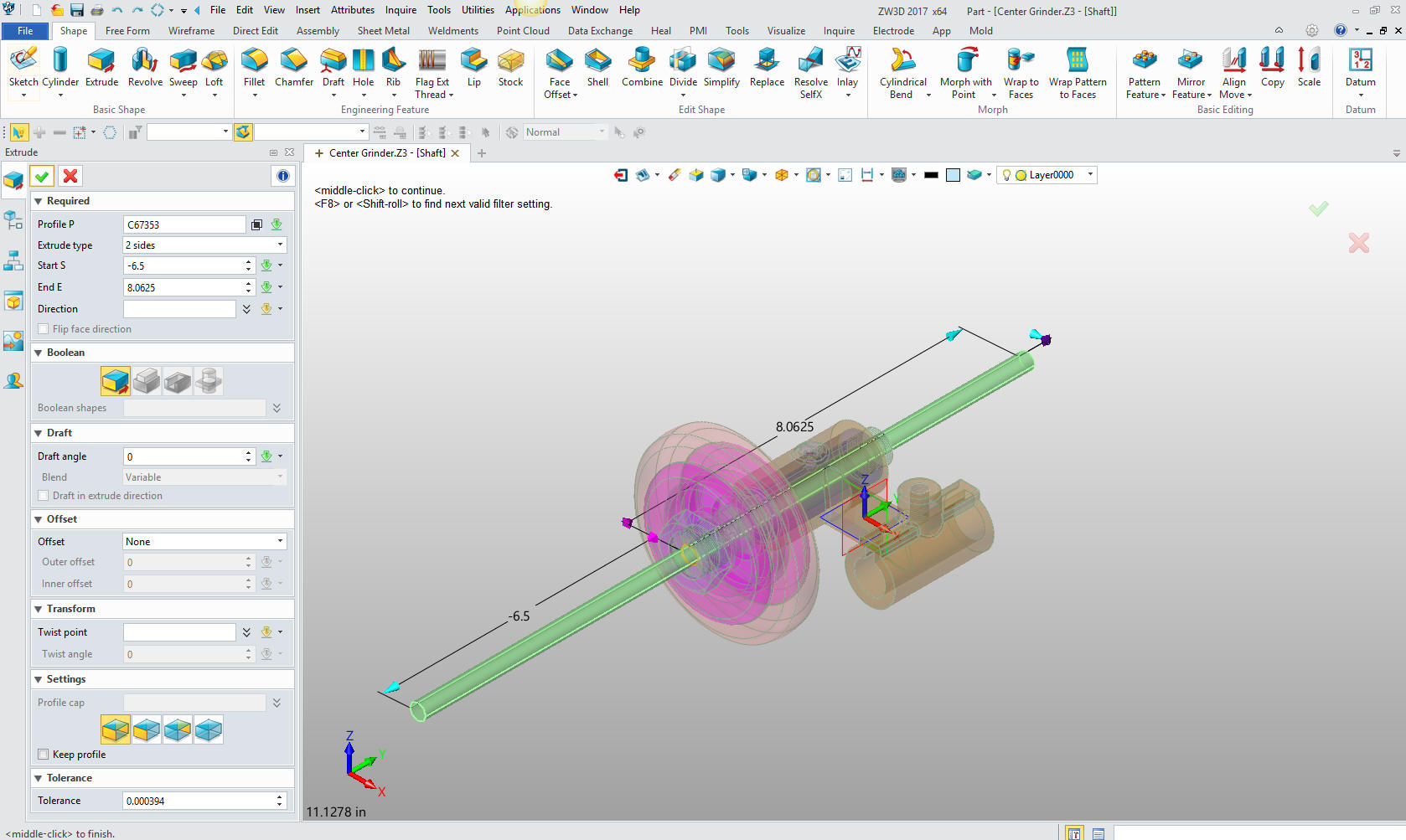

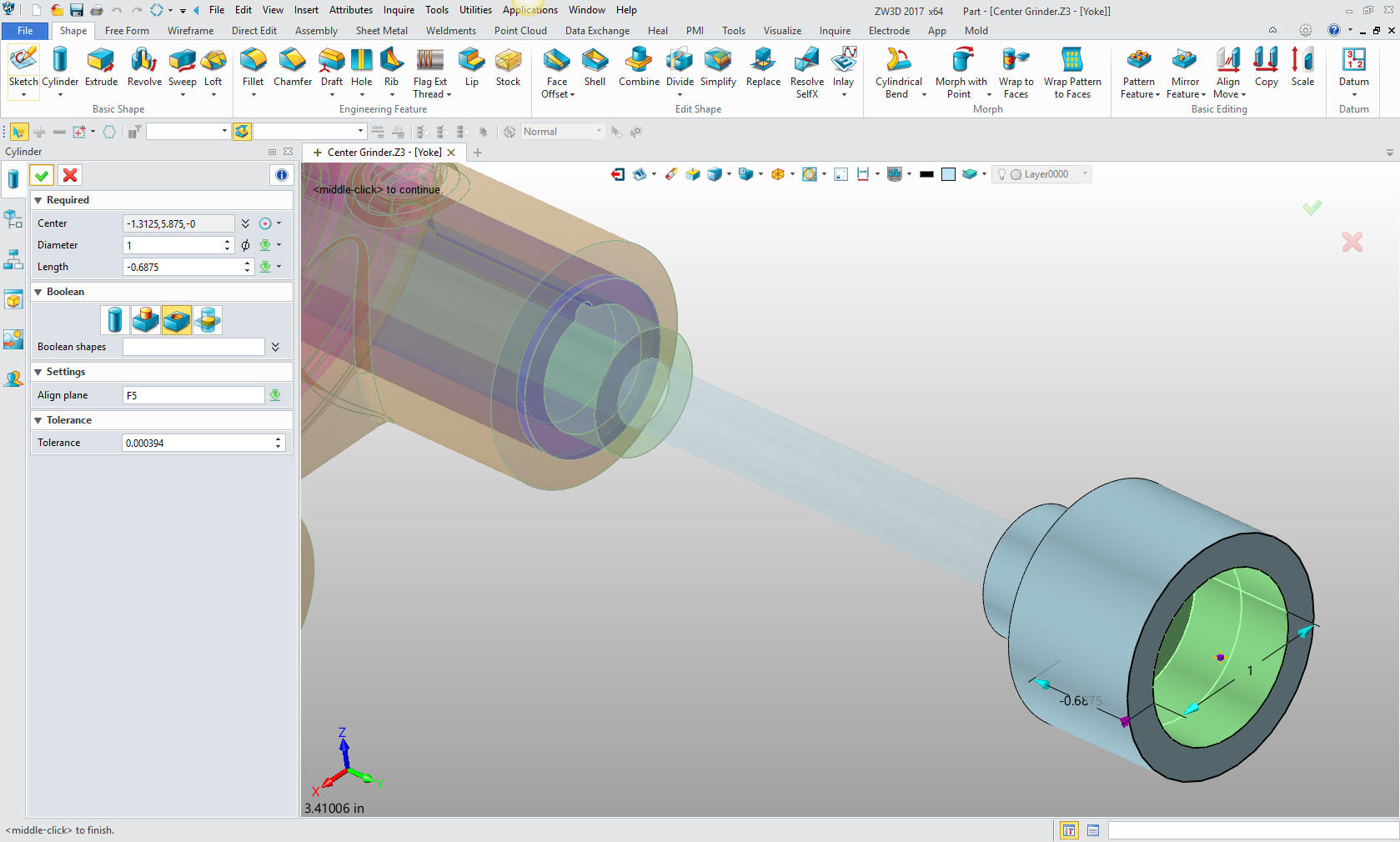

We now

insert a primitive cylinder using the center of the reference

entity. I think this is one of the few programs that allow a

reference graphic drive an extrusion. This feature was available in CADKEY

where planes were implied.

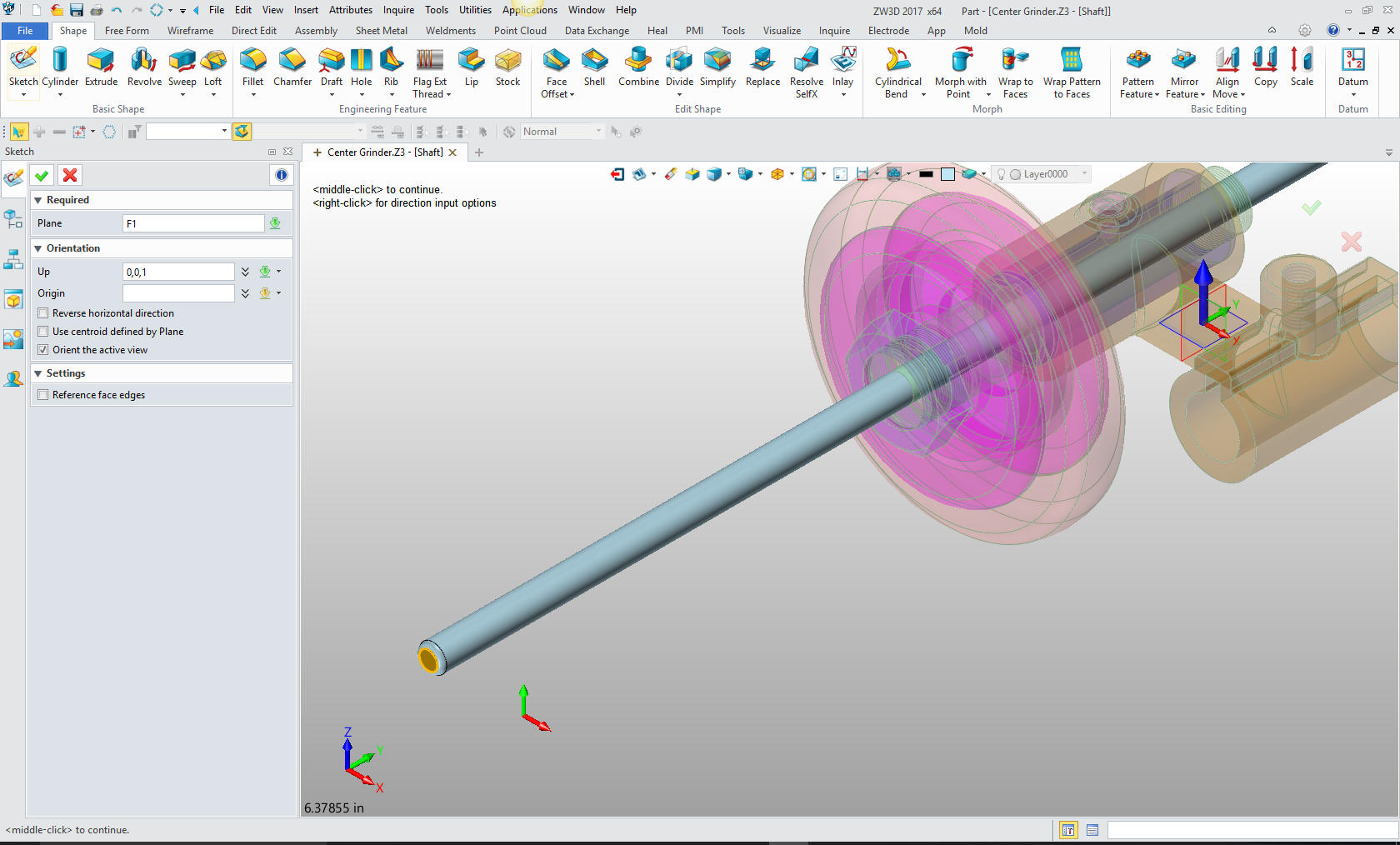

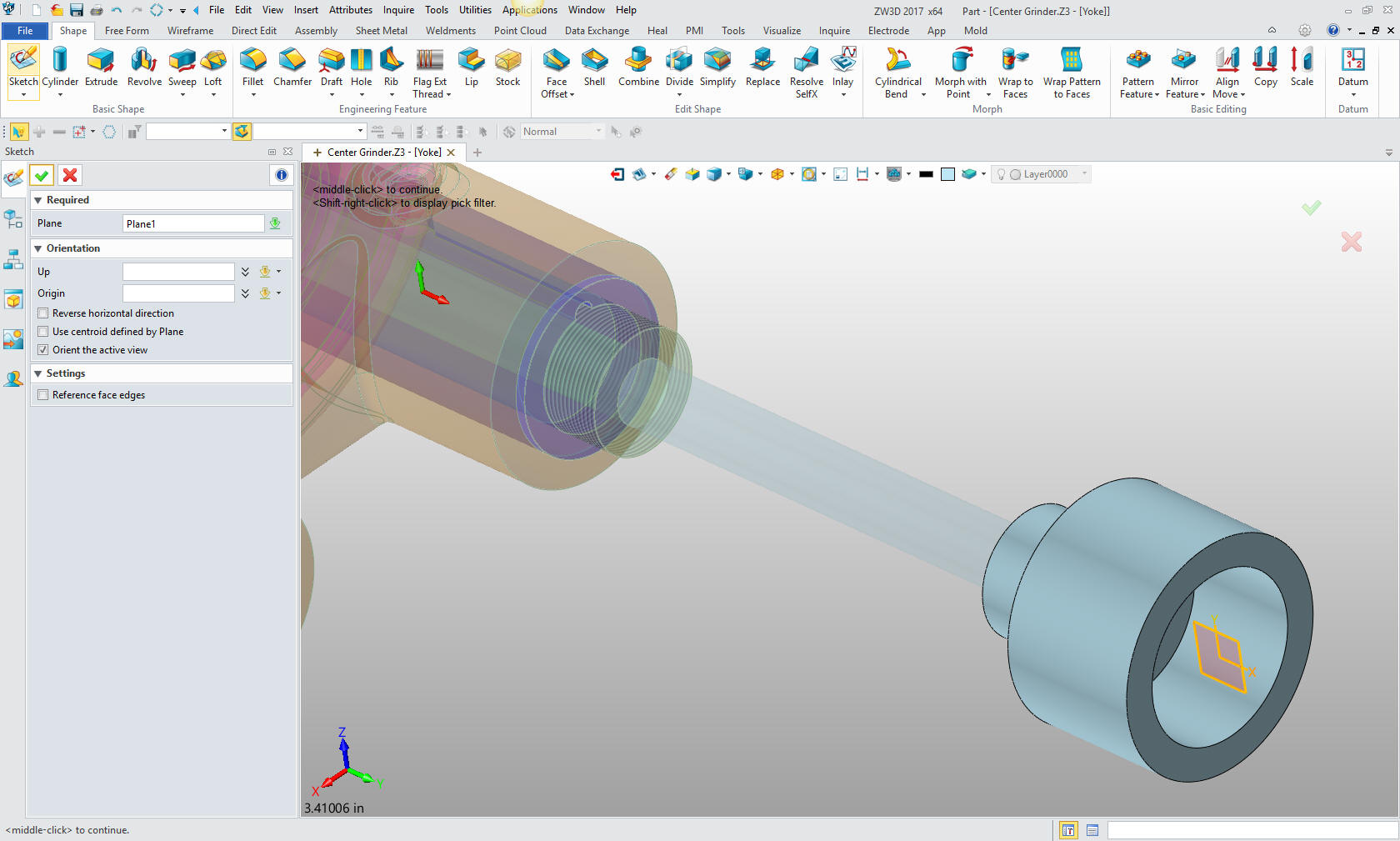

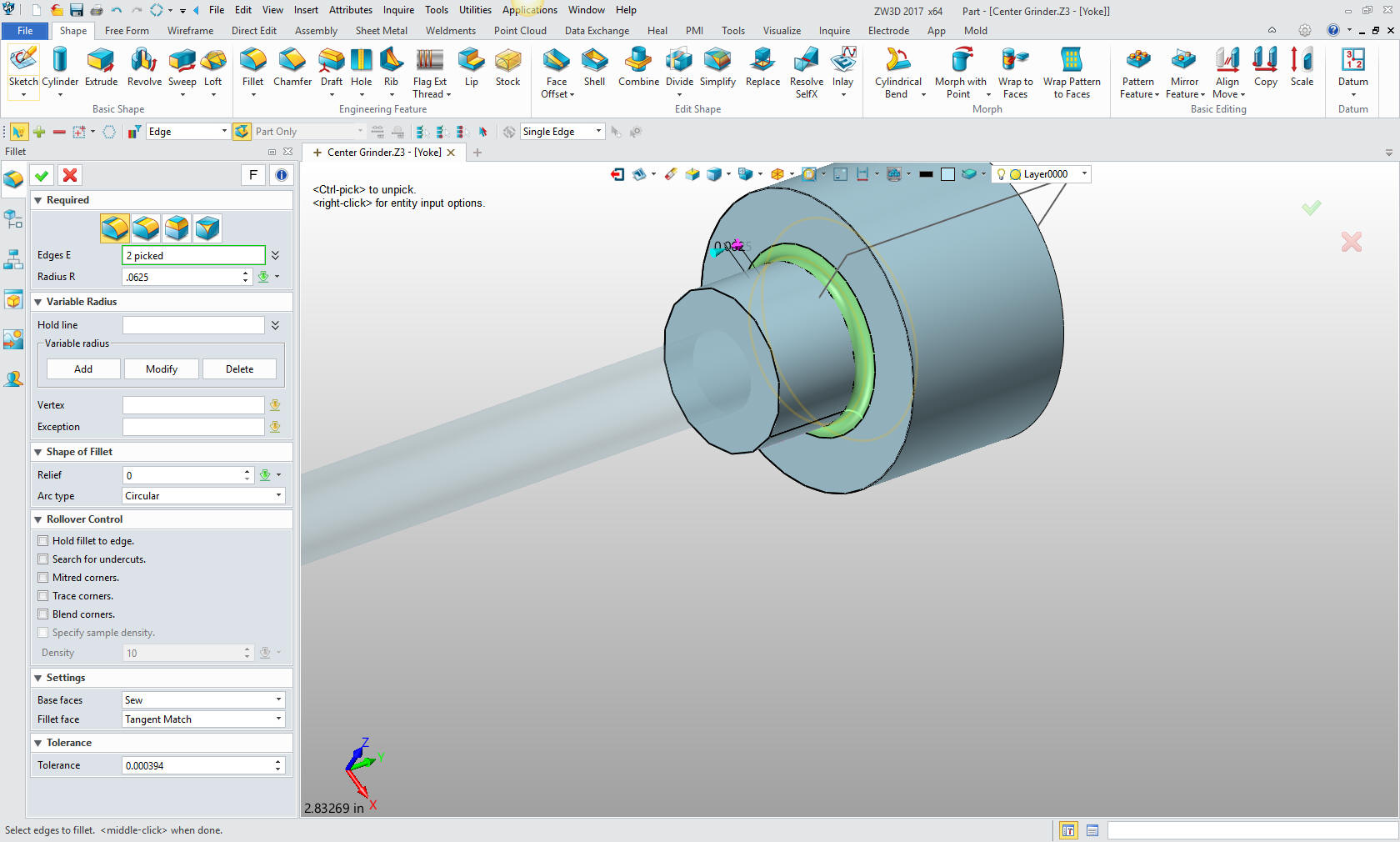

We

add the blends to the ends and sketch the groove on the bottom. We

create the sketching plane on the end of the shaft and select the Z

axis for the up direction.

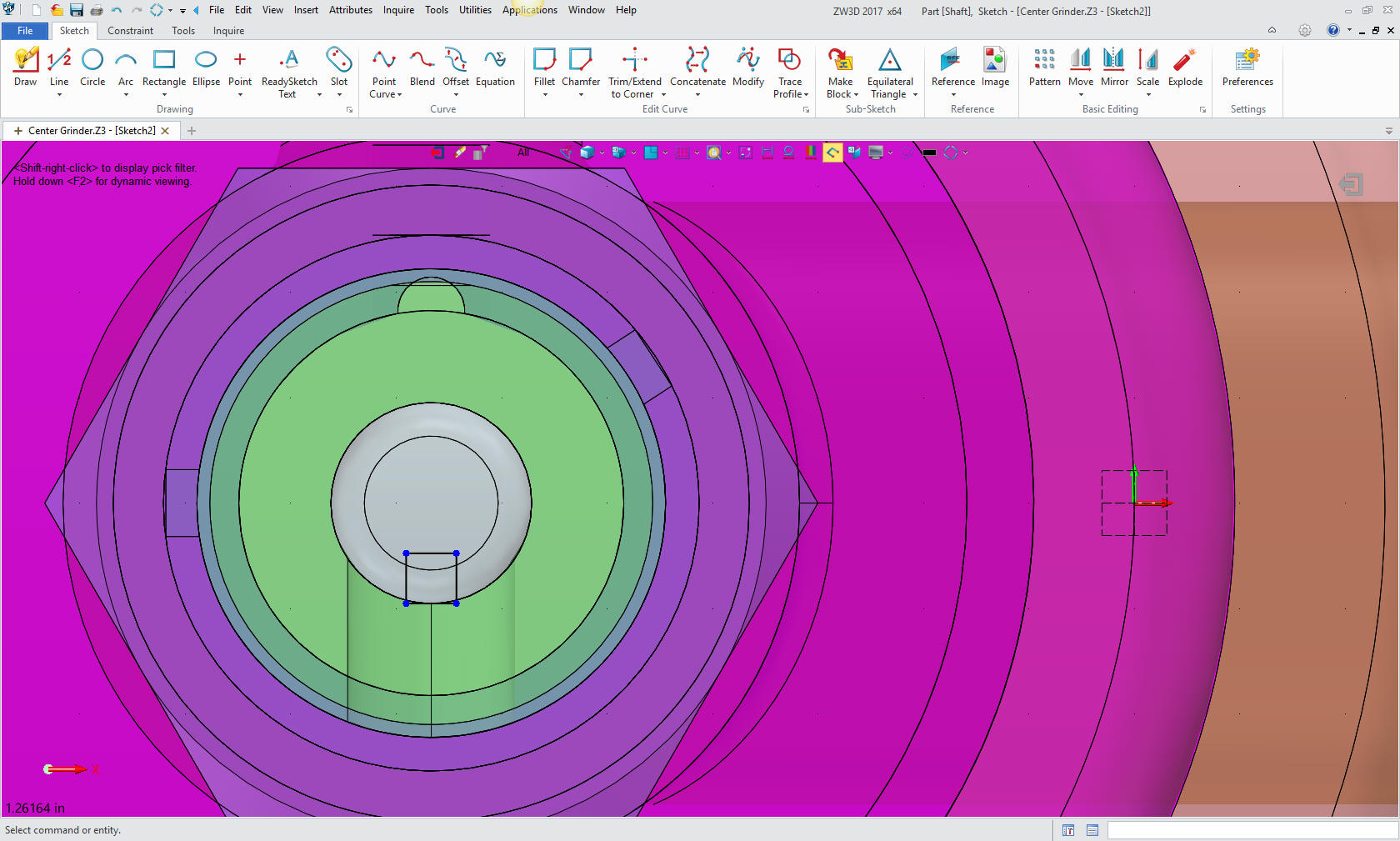

Now we

skectch the cut for the grooves.

We

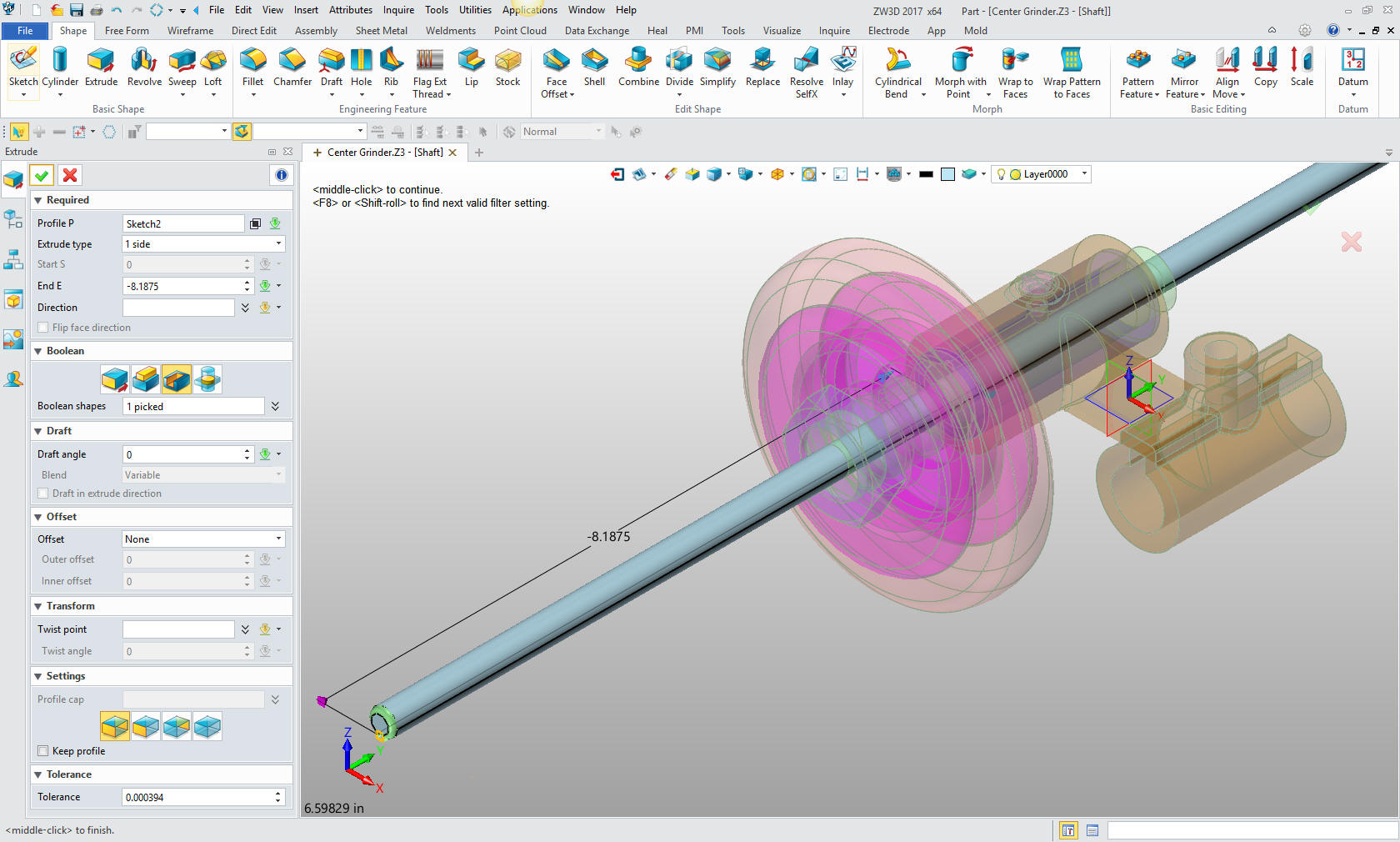

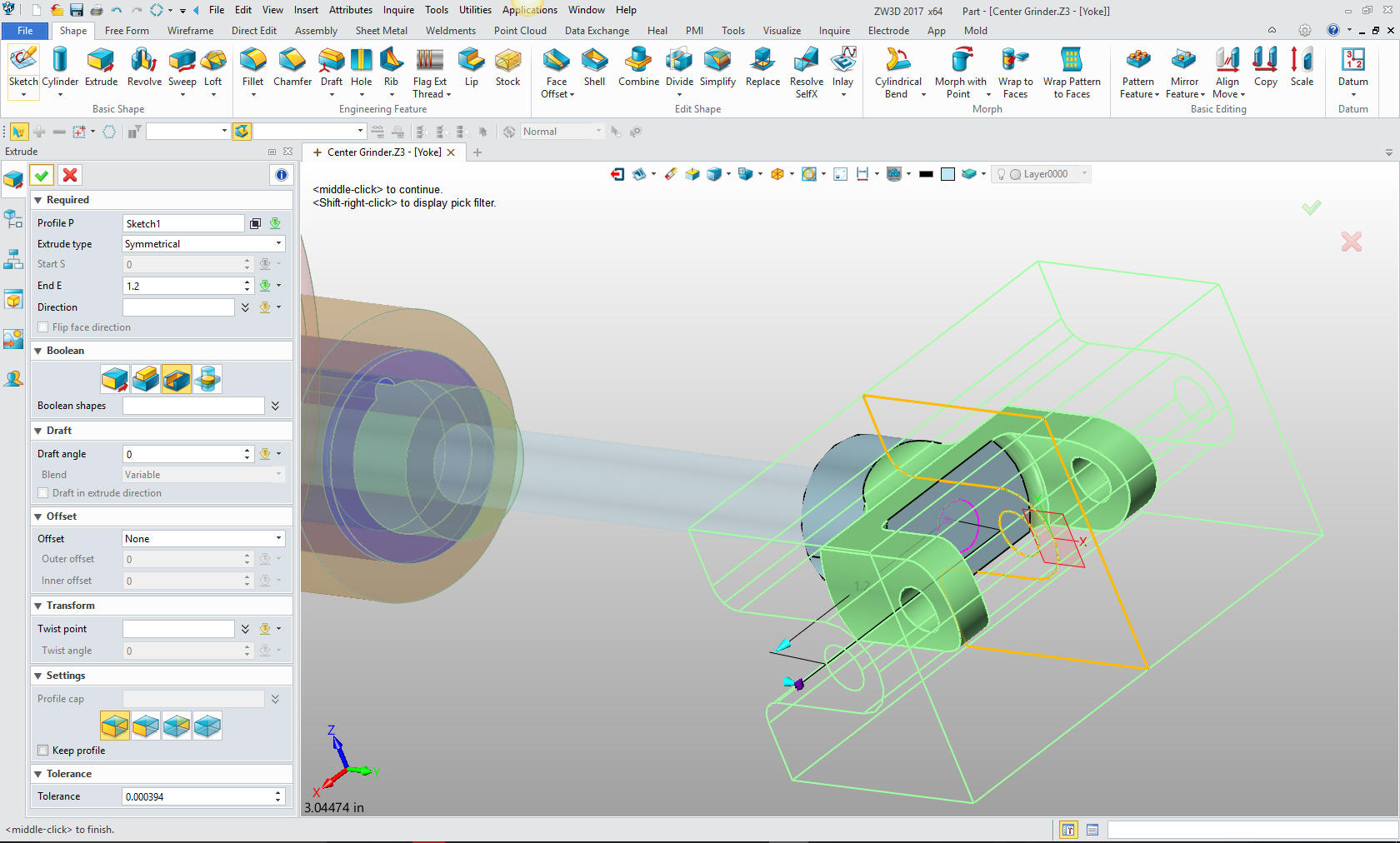

exit and extrude the profile to the defined depth.

I just

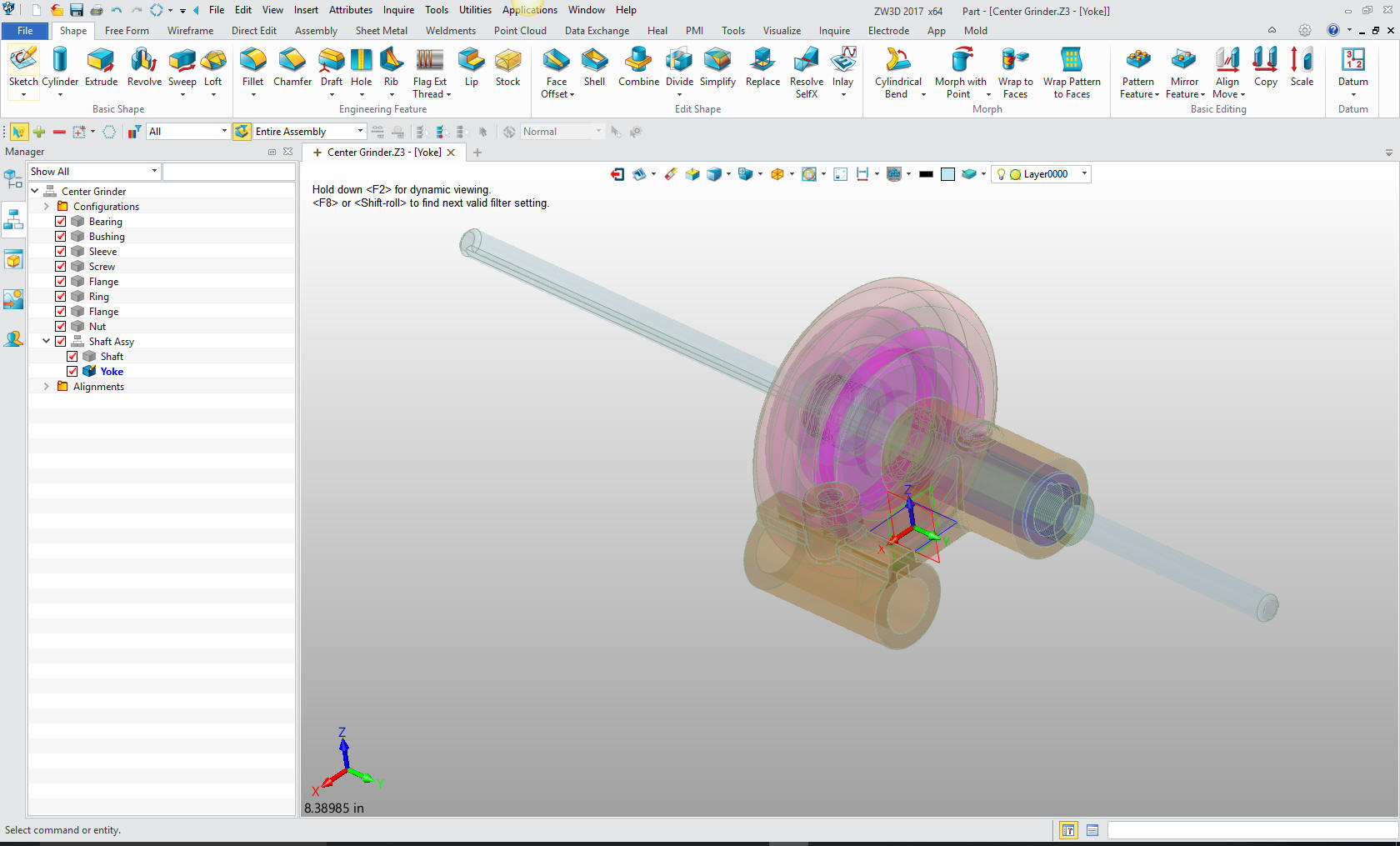

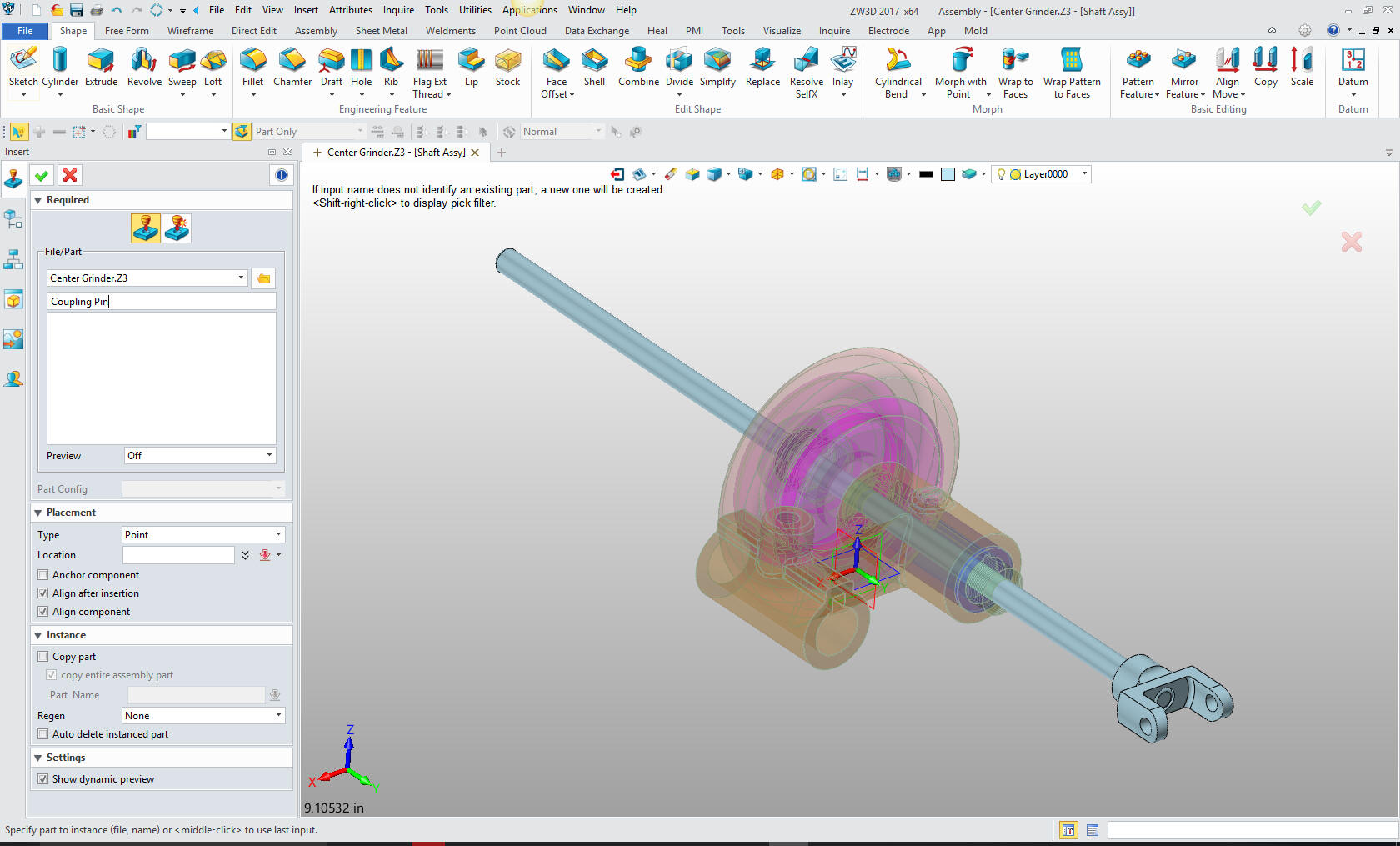

realized that the shaft and yoke are an assembly. I will now insert

a new component called Shaft Assy and drag the shaft into it then

insert a new part called yoke. We will rotated it to get to the

location to design in context. I design in context to have the parts

in car or aircraft position. I do this so I can work back and forths

with ironCAD.

We

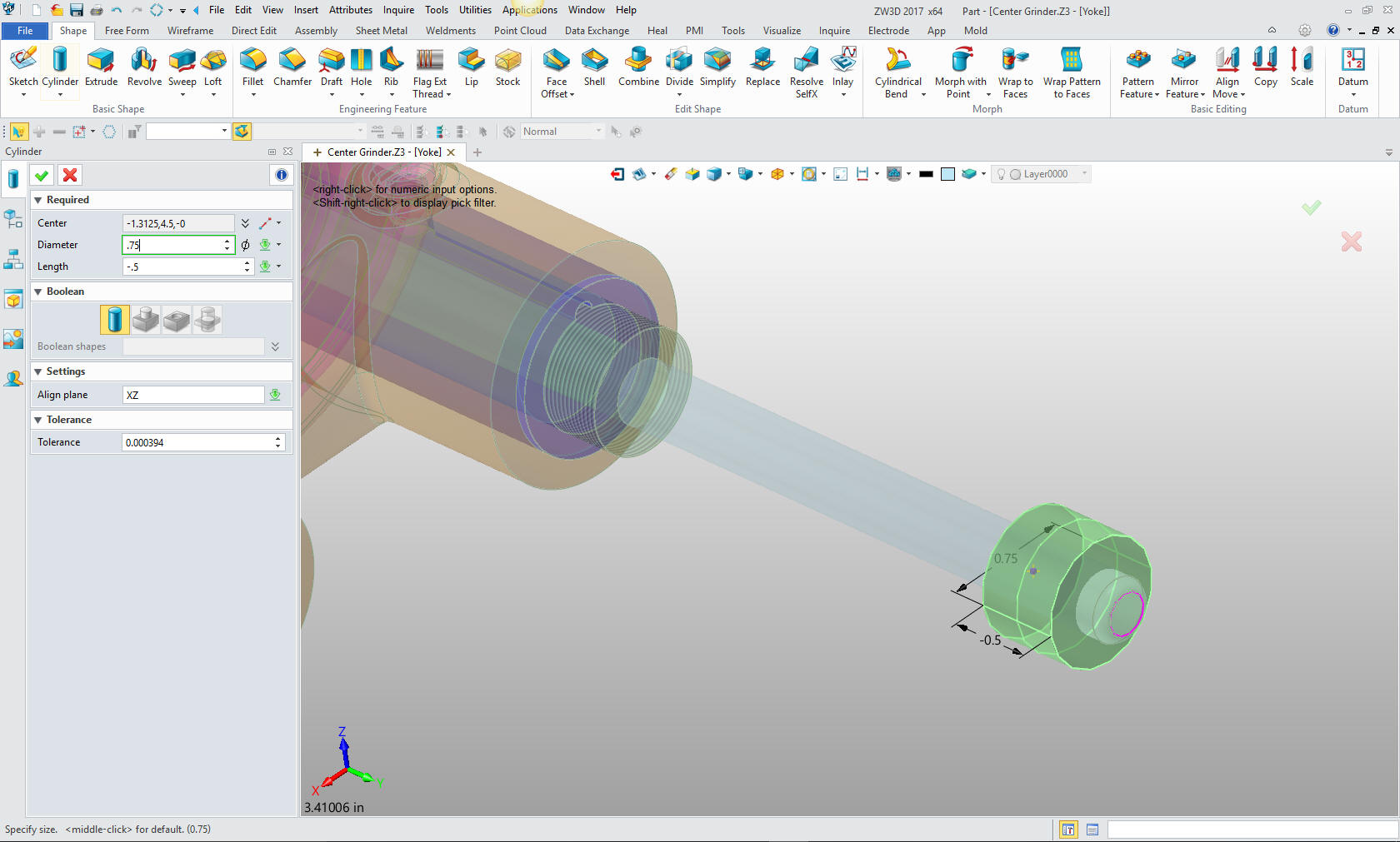

will now create the yoke by creating reference on the end of the

shaft. We insert a primitive cylinder, locate it and size it.

We

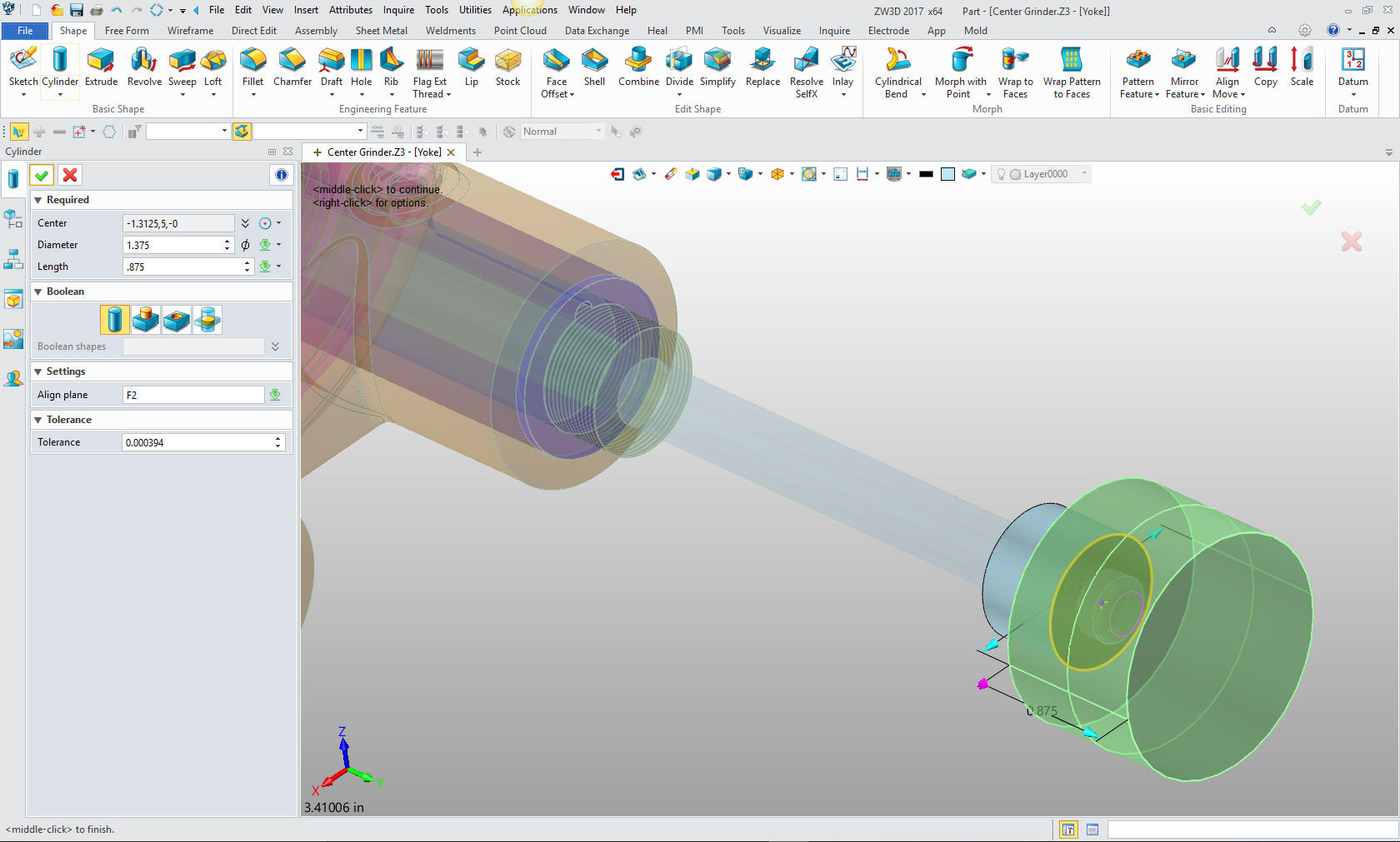

again insert a primitive cylinder on the center of the face of the

existing cylinder and size it

Now we

will again insert a primitive cylinder at the center of the face and

size it.

We

will now make the outside cut by sketching the profile. First we

will insert a plane to work with.

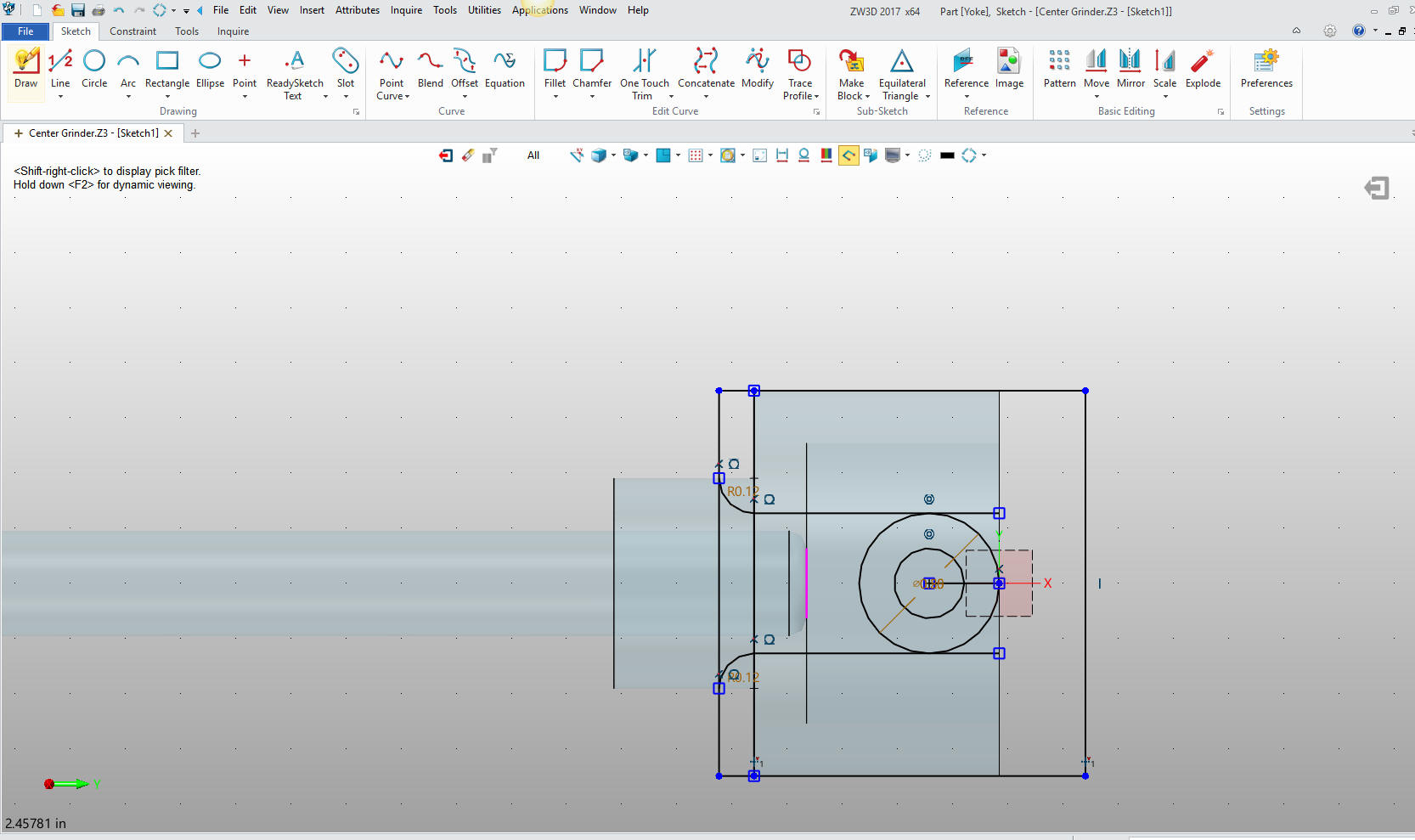

We now

create the sketch. Here is the sketch with some of the graphics I

used to create the profile.

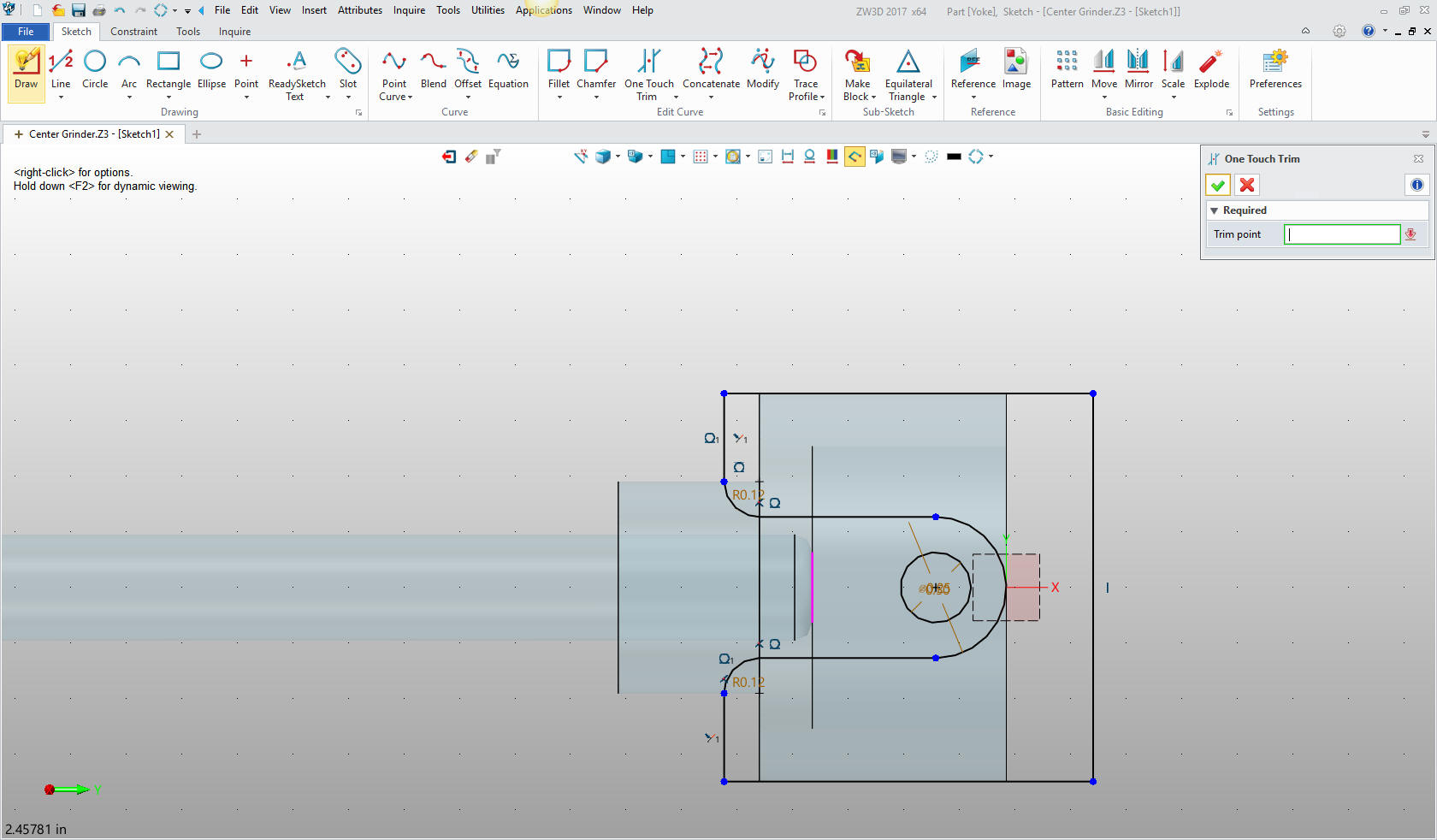

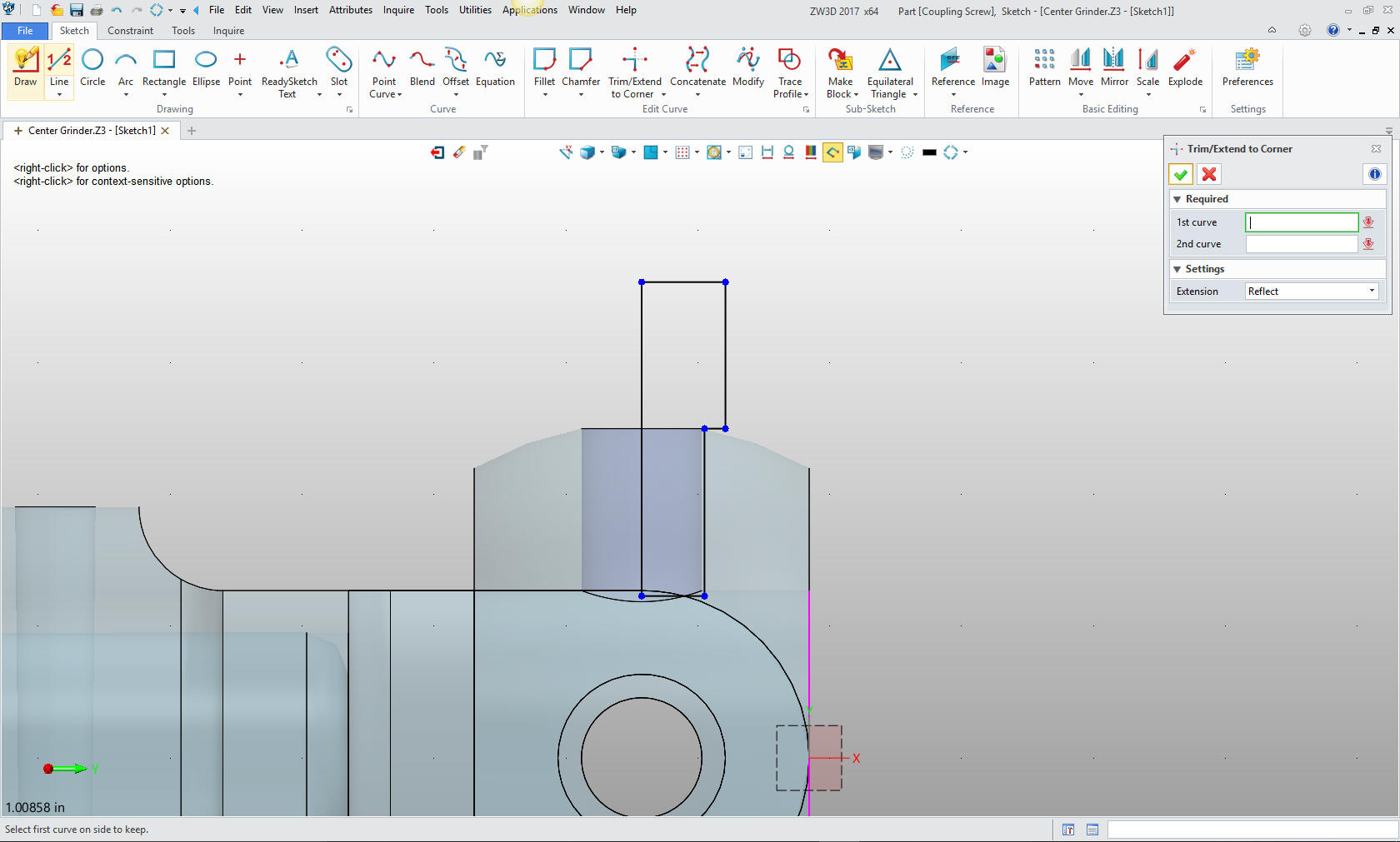

Here is the

final profile with the lines trimmed, extended or deleted.

We

will add the radii before we make this cut

Now to

extrude the profile.

Add

the last hole and we are done with the part.

We

will now add the Tapered pin that gets drilled at assembly. We will

again insert a new component under the Shaft assembly.

We

create a reference circle that we will use to create a plane. Whew,

these planes are a bit of a hassle. I am not used to it but getting

better.

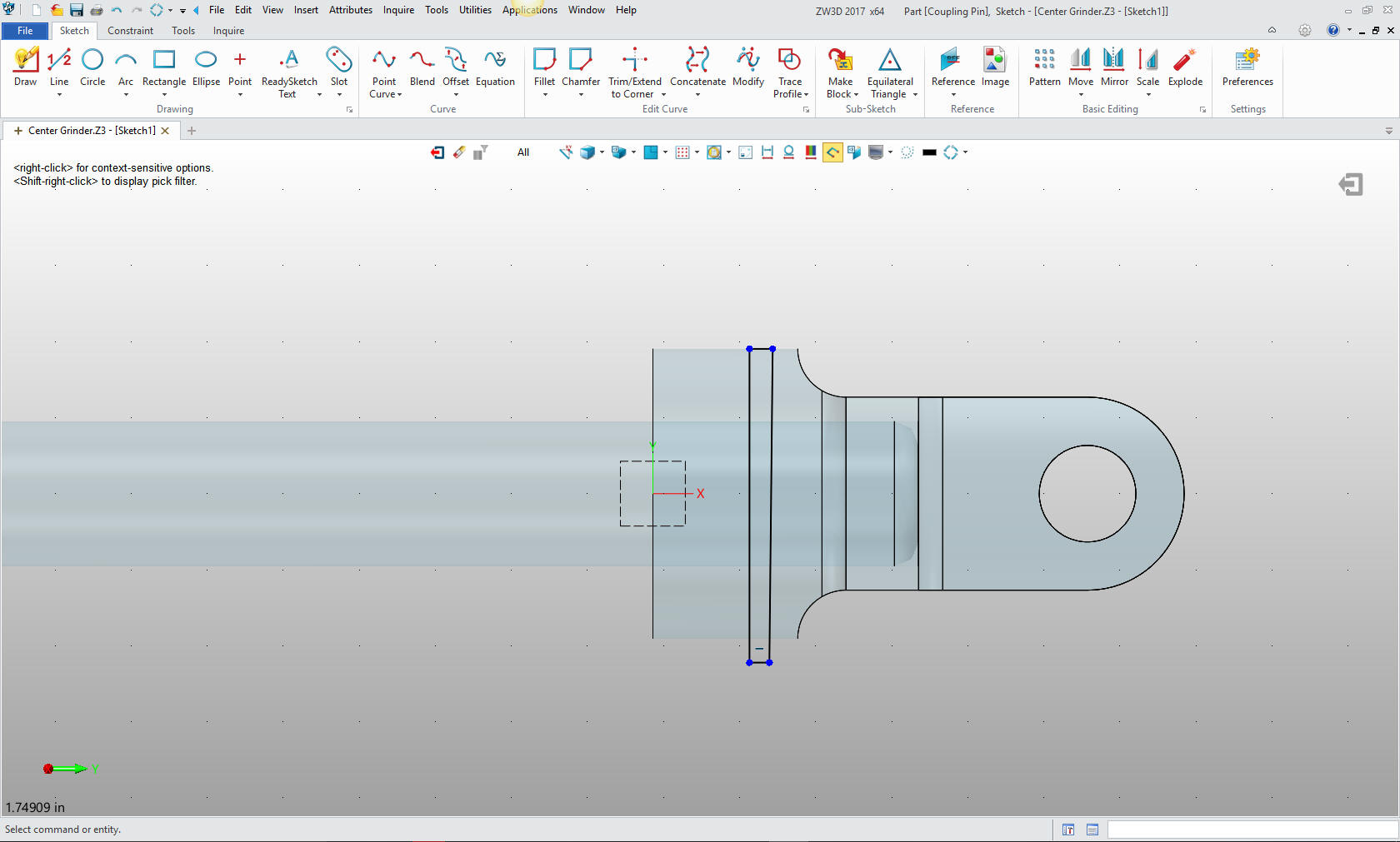

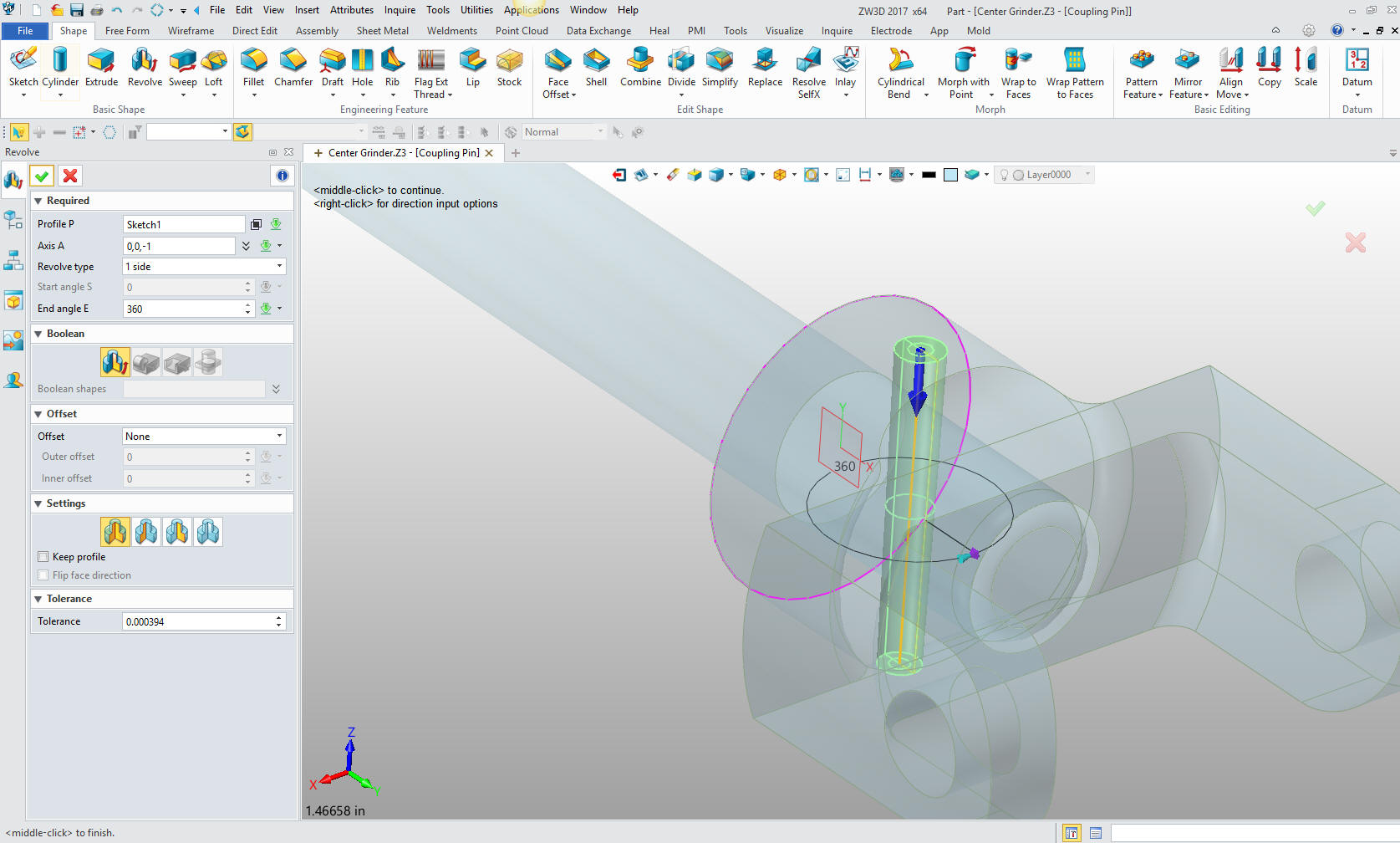

Now

for the taper pin sketch which we will be revolving.

Now we

have the pin. We will not create the hole in the parts.

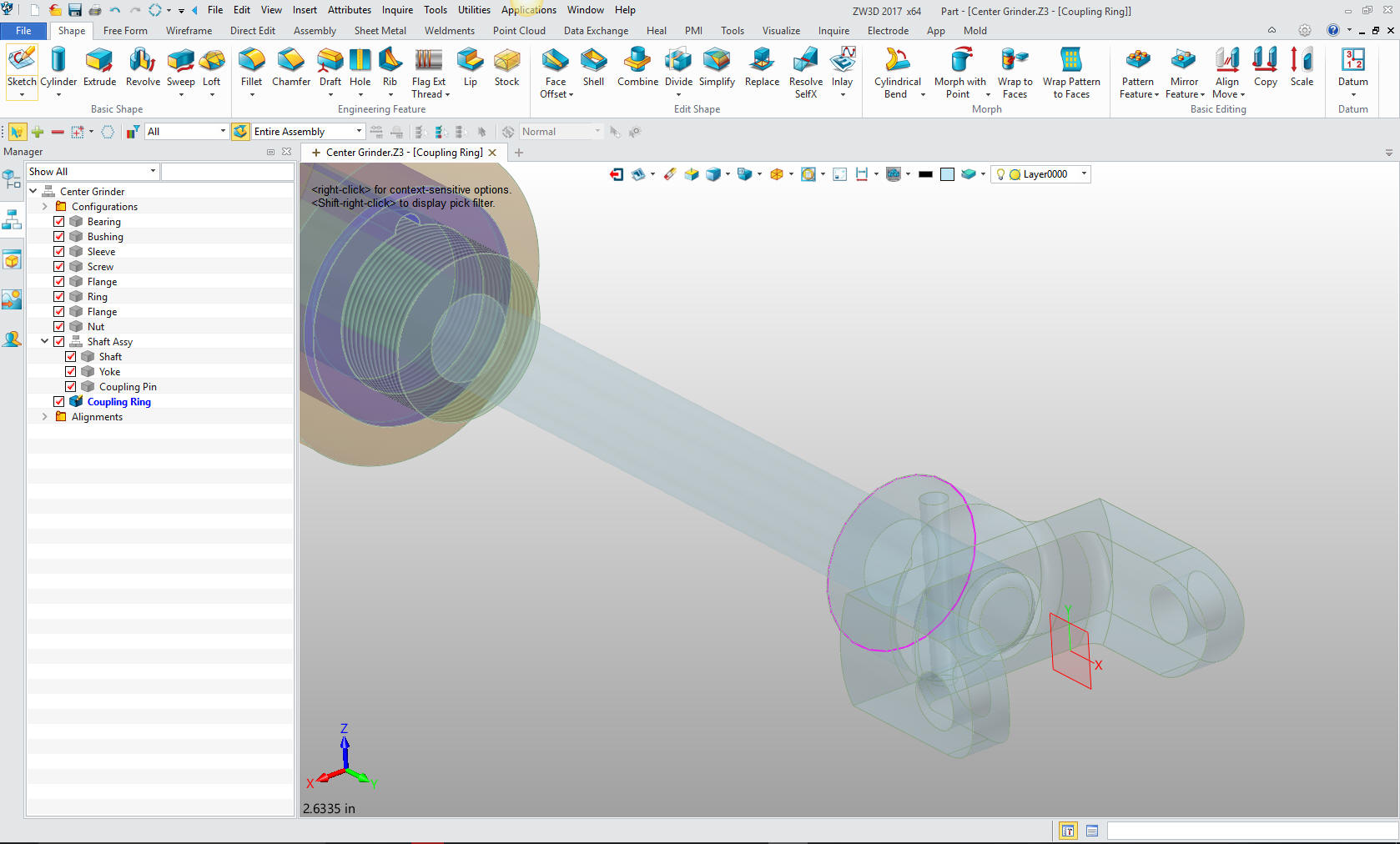

We now

insert another component under the center grinder assembly and name

it Coupling ring. Another plane.

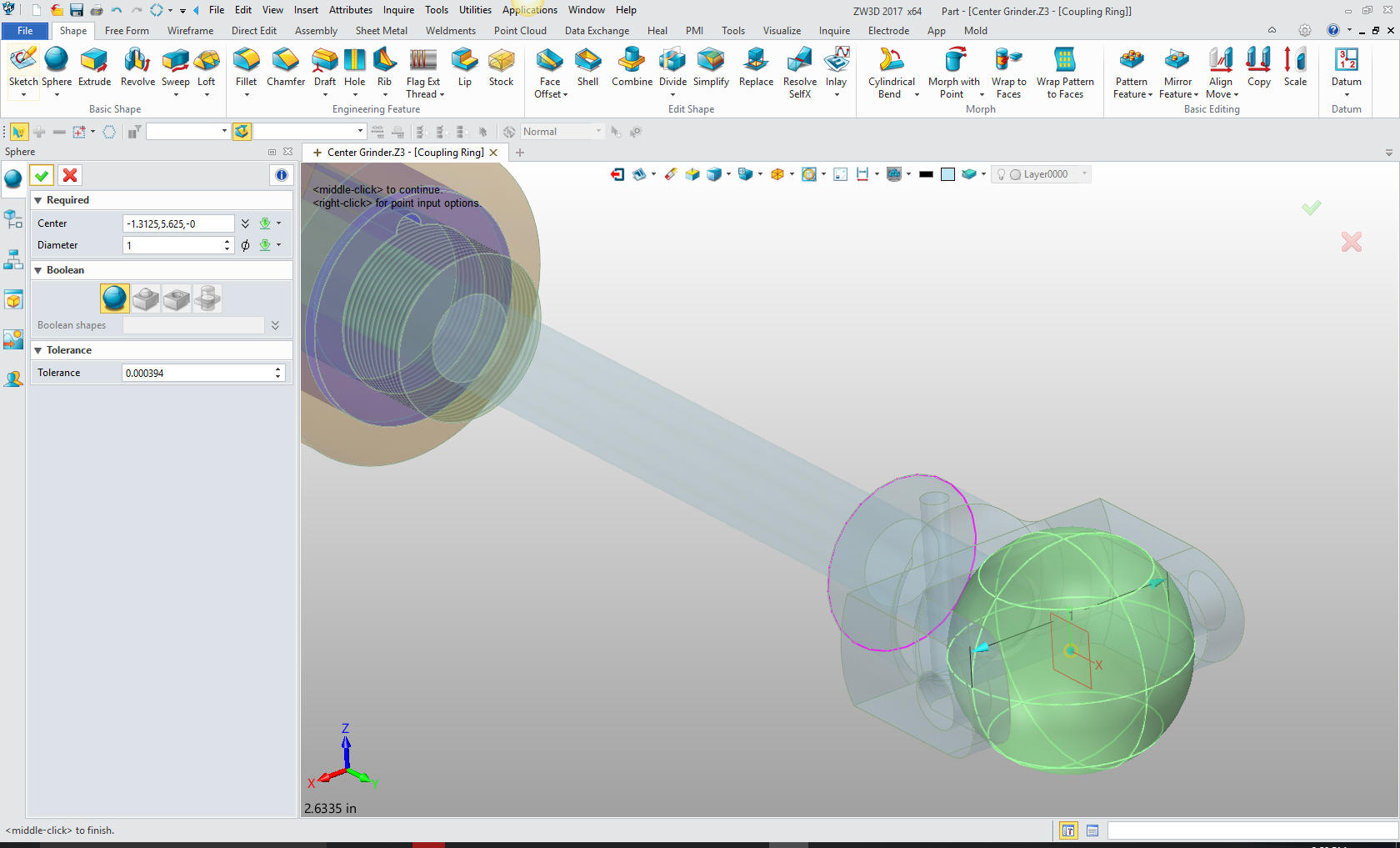

Now we insert a primitive sphere and size it.

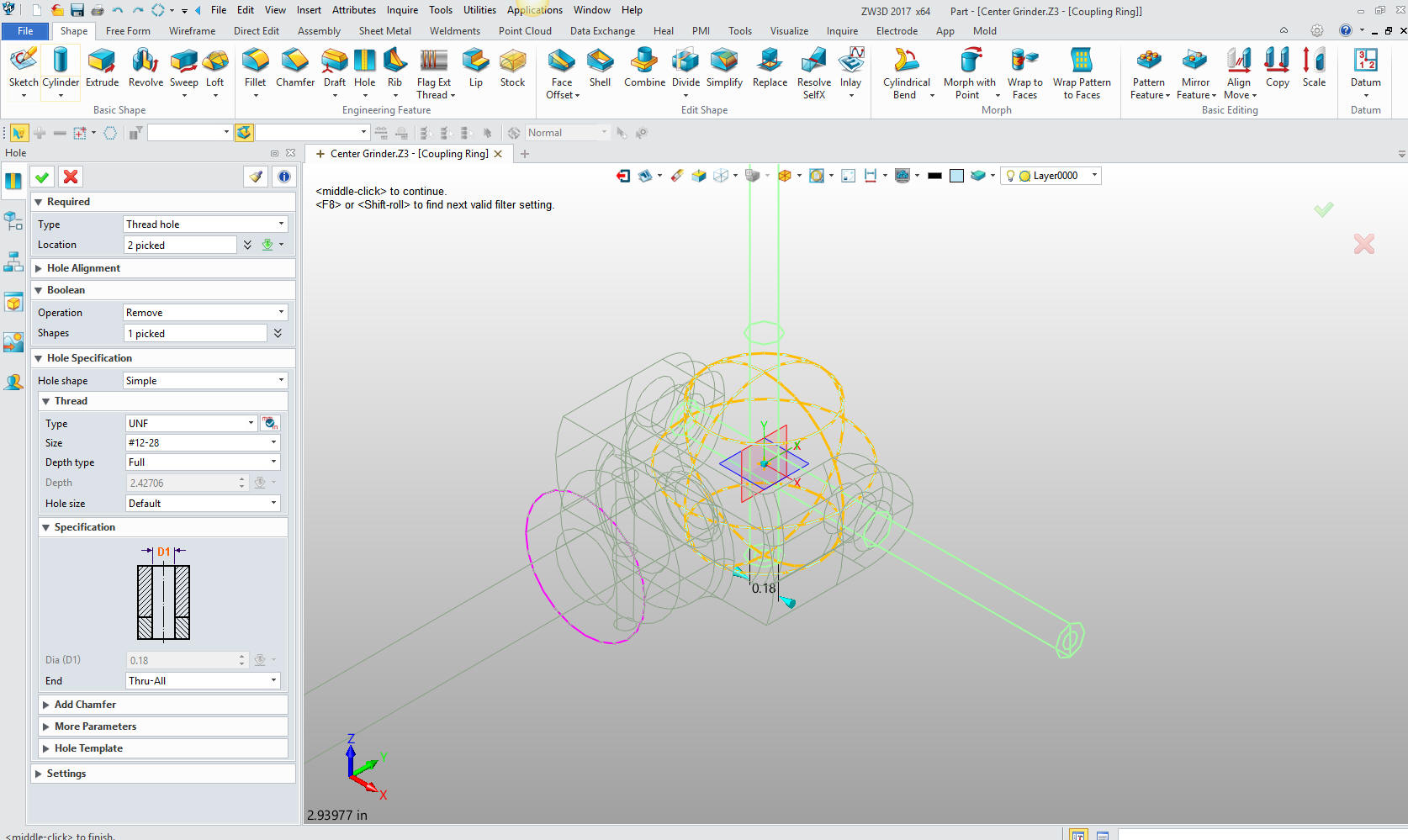

We

will add the threaded holes prior to the cuts to make sure the go

through the sphere.

With

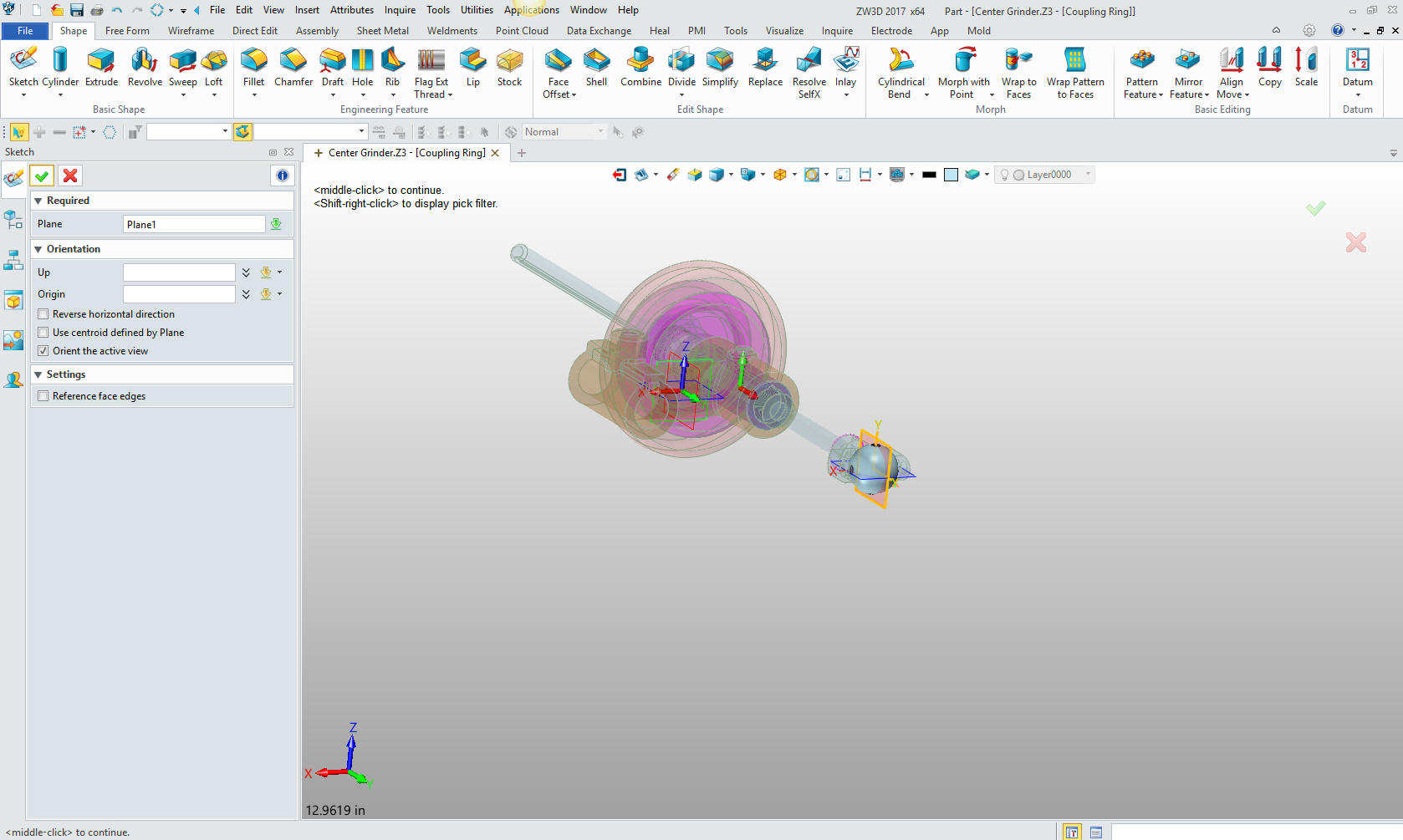

the holes done we will create the sketch cut for the sphere. I have

been going to wire frame to select the plane. But you can zoom out

and the planes stay the same size allowing you to select the plane.

Not a big deal but save a bit of time.

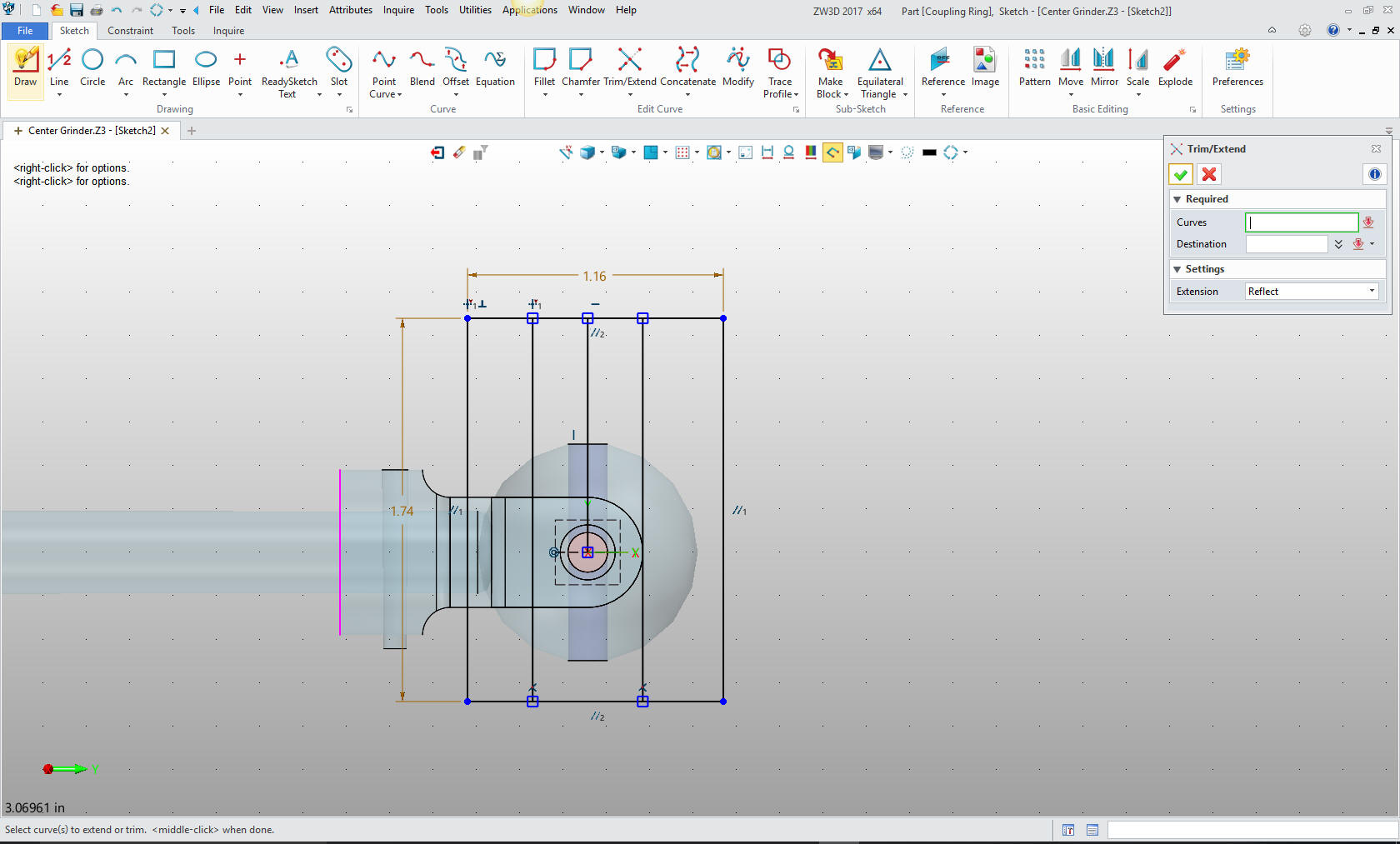

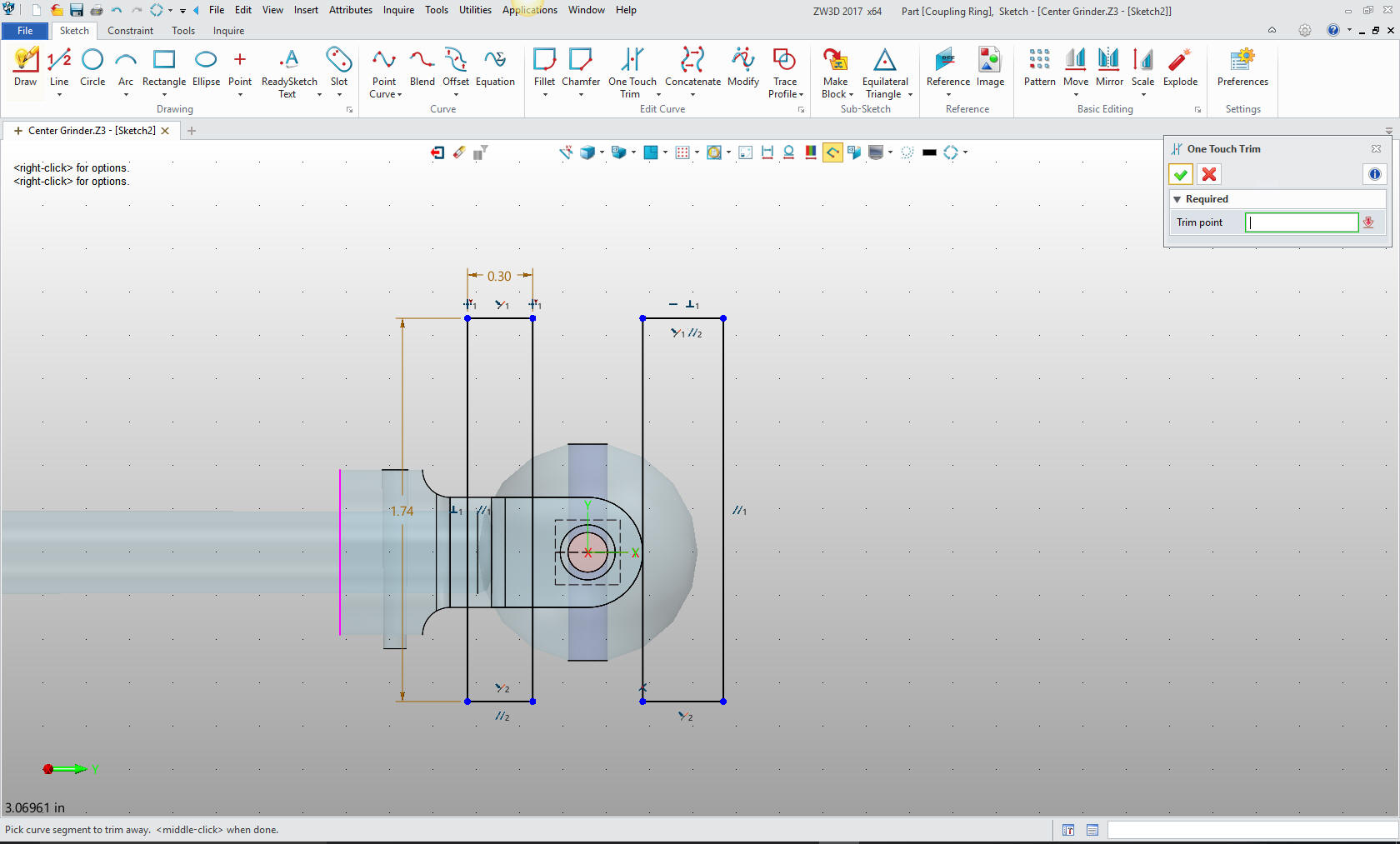

Here the sketch. I create a vertical line off the center of the

sphere, then offset .250, then trim, extend and delete the lines. No

constraints.

The final profile.

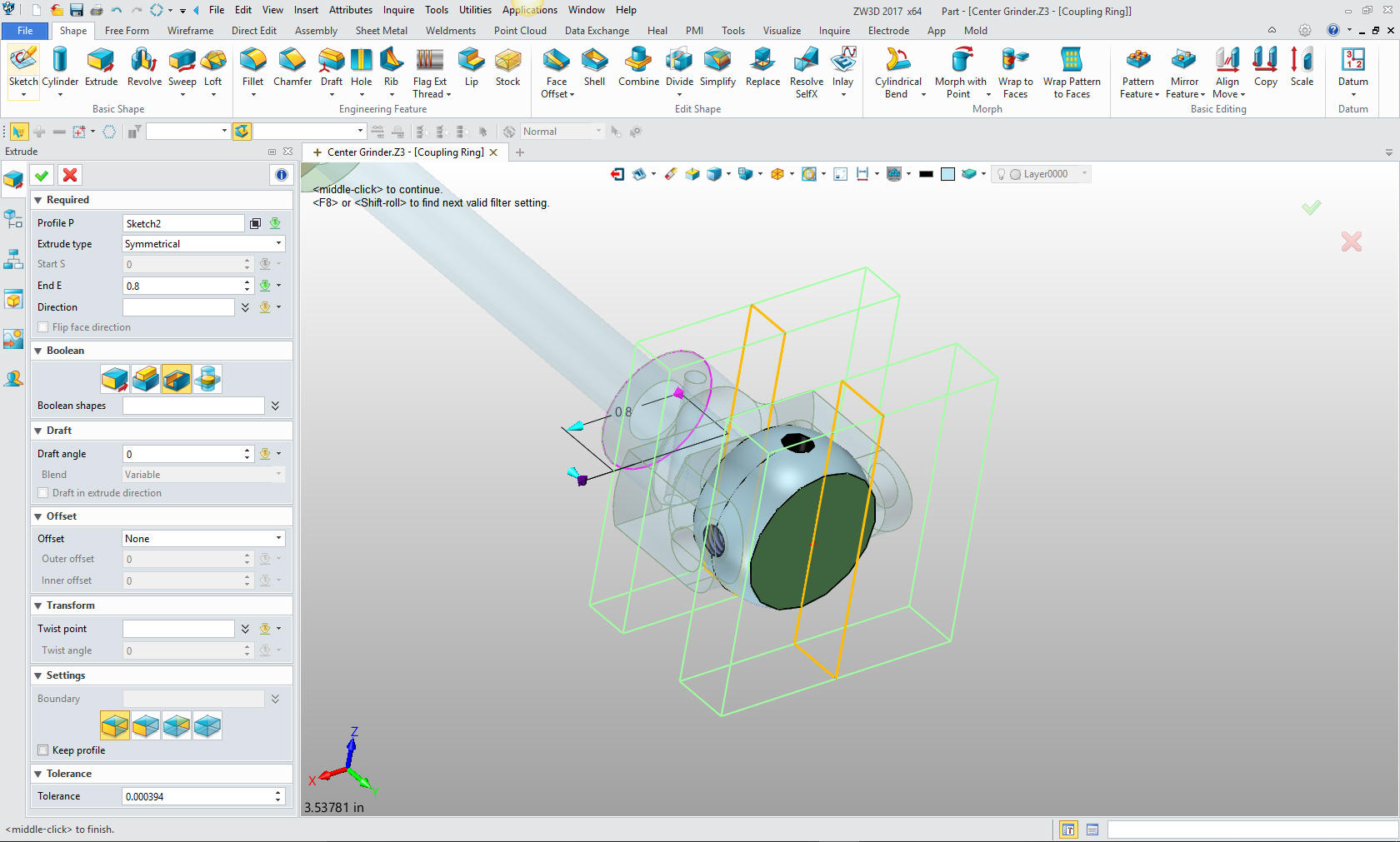

Now we

extrude the cut.

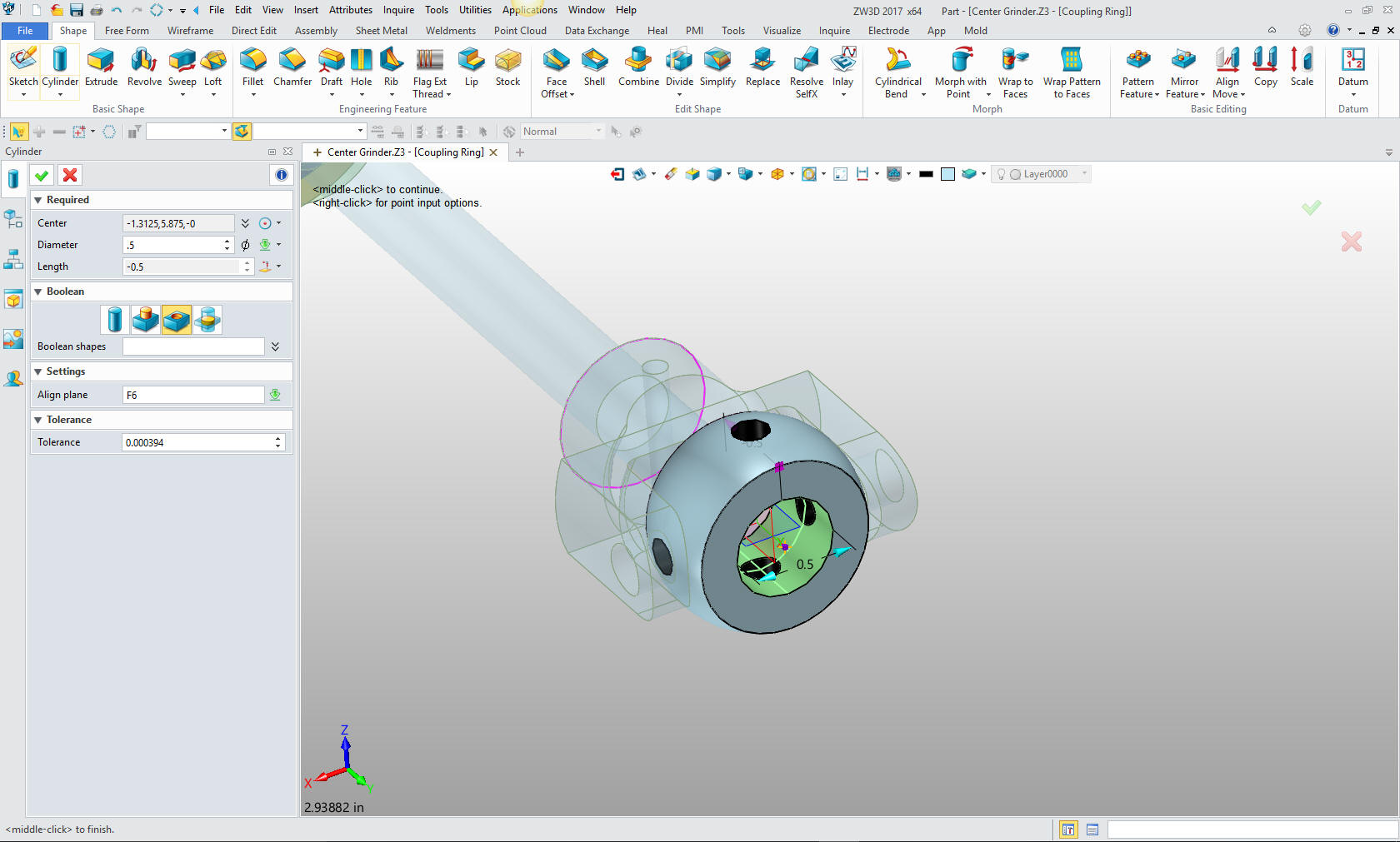

We

insert a cylinder at the center of the affected face and we are done

with the part.

We

have to create another place at the center of the sphere to create

the holes.

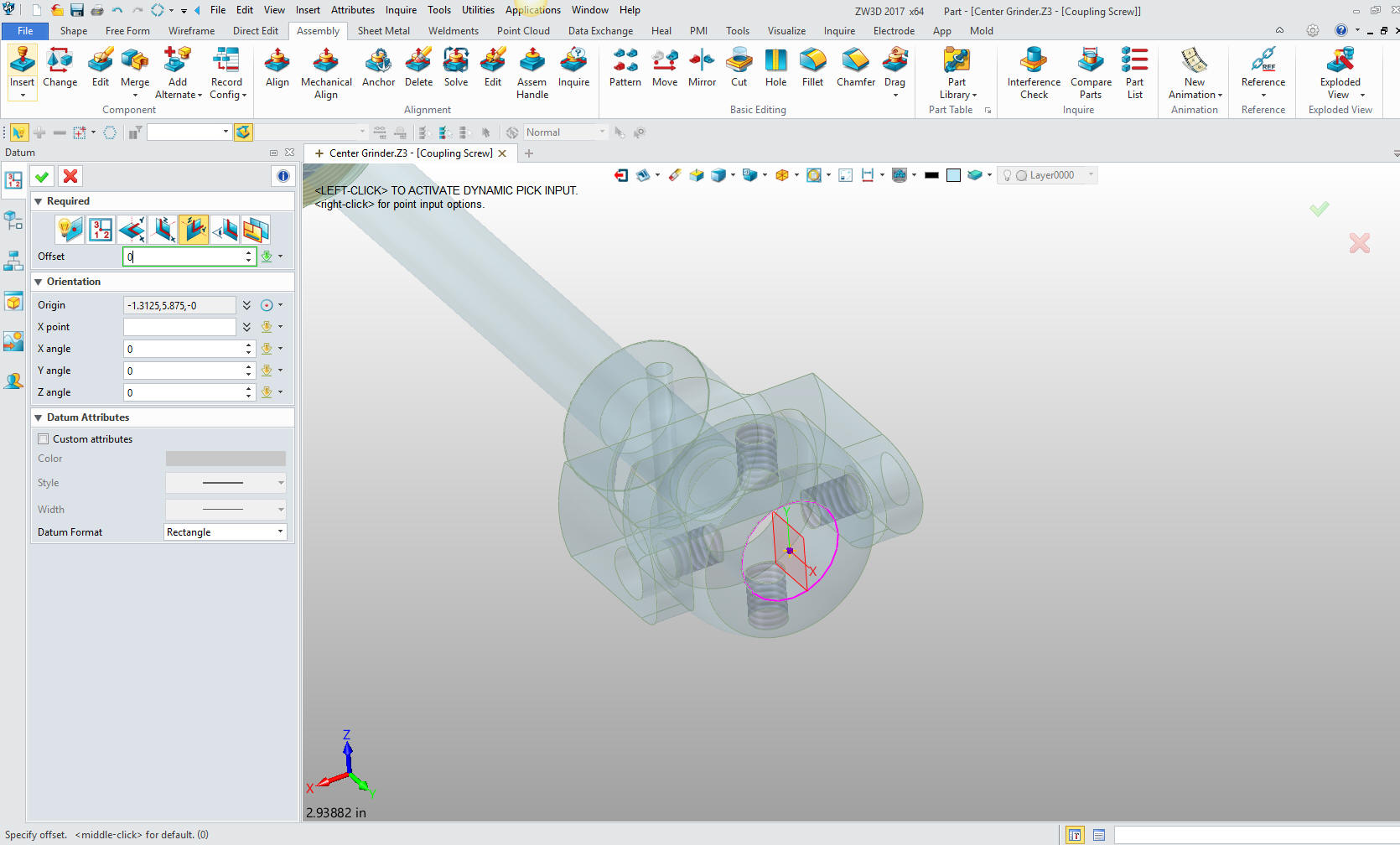

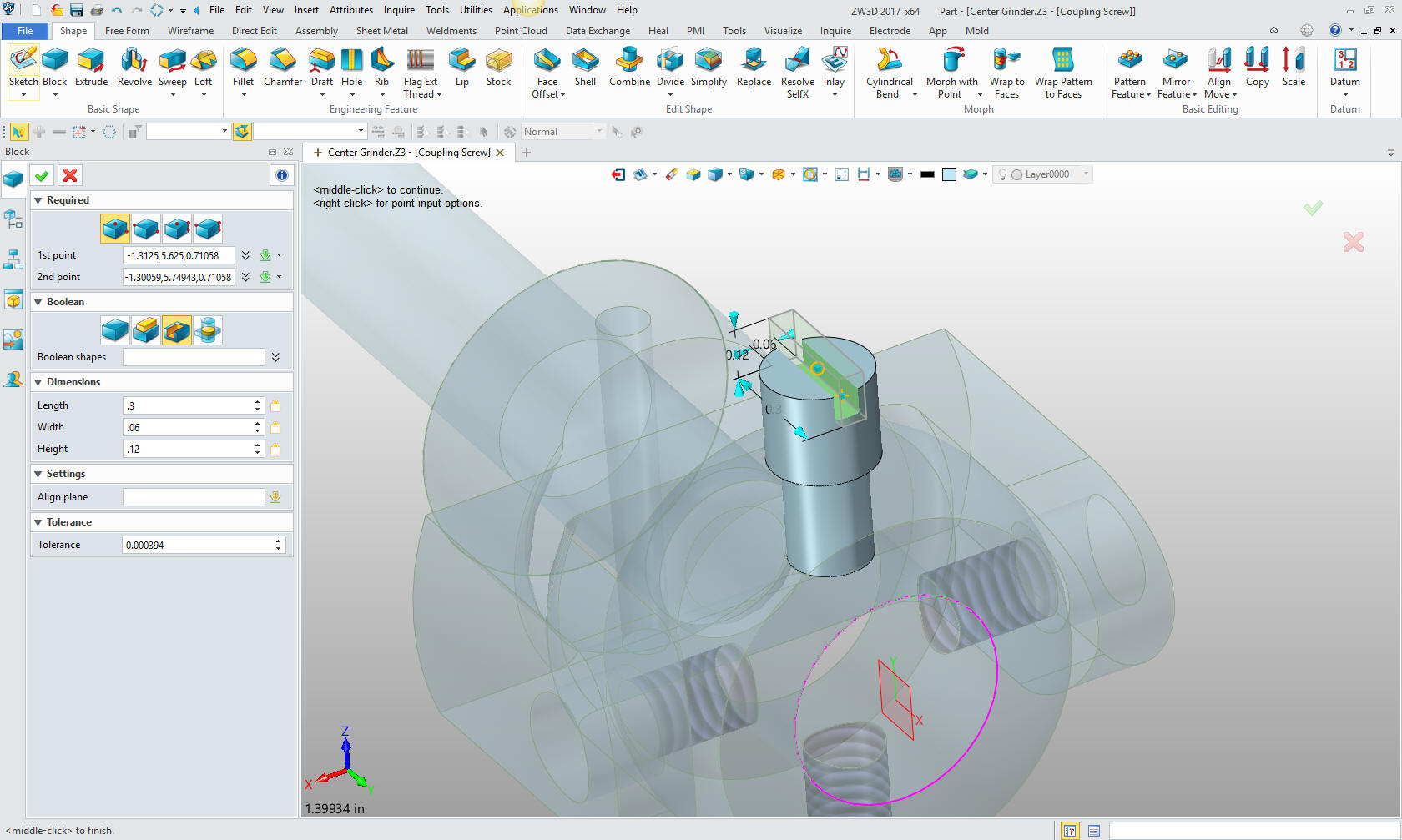

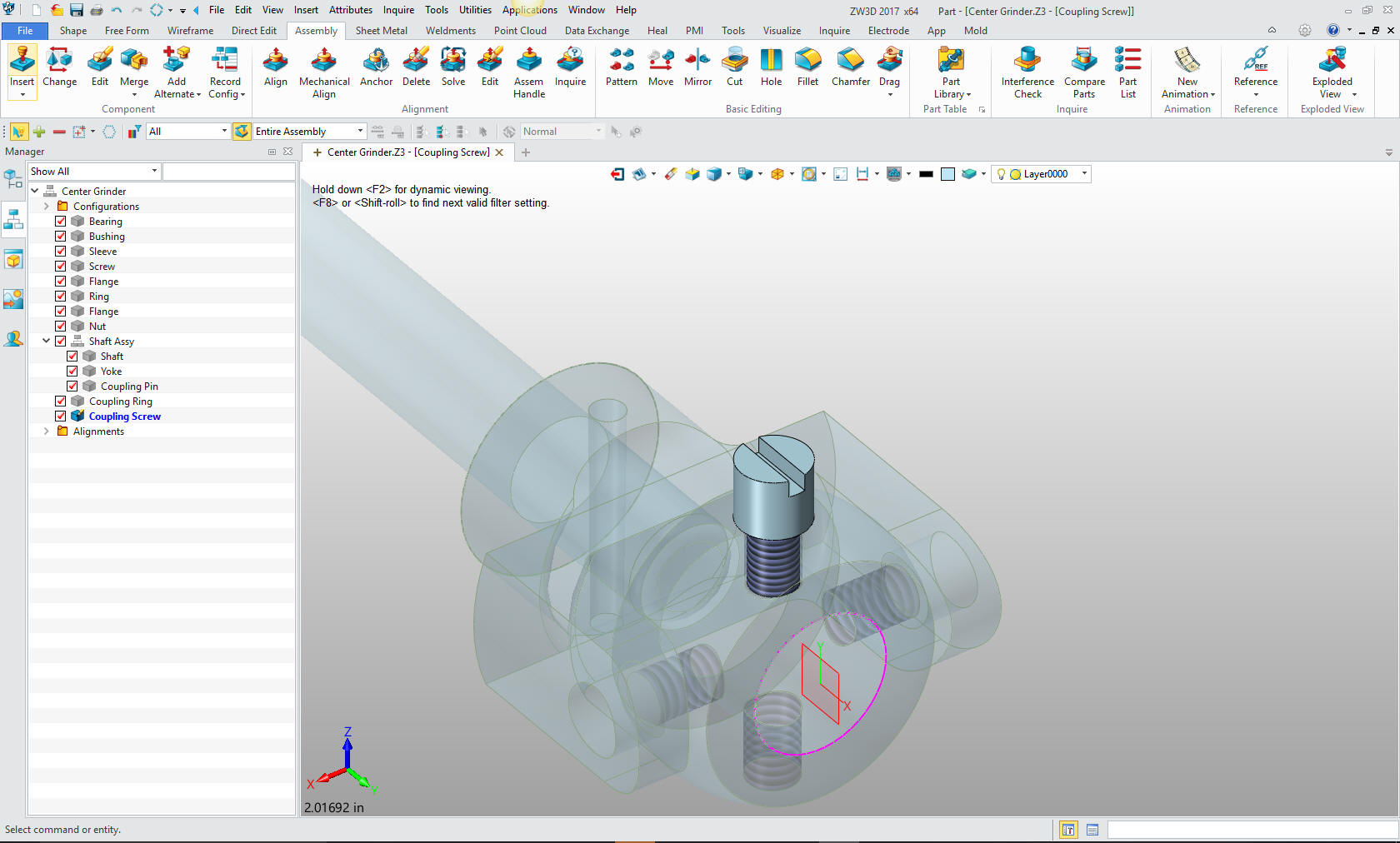

We insert the component Coupling Screw under the top Center Grinder

assy. We create a reference circle and create a plane in the center.

I

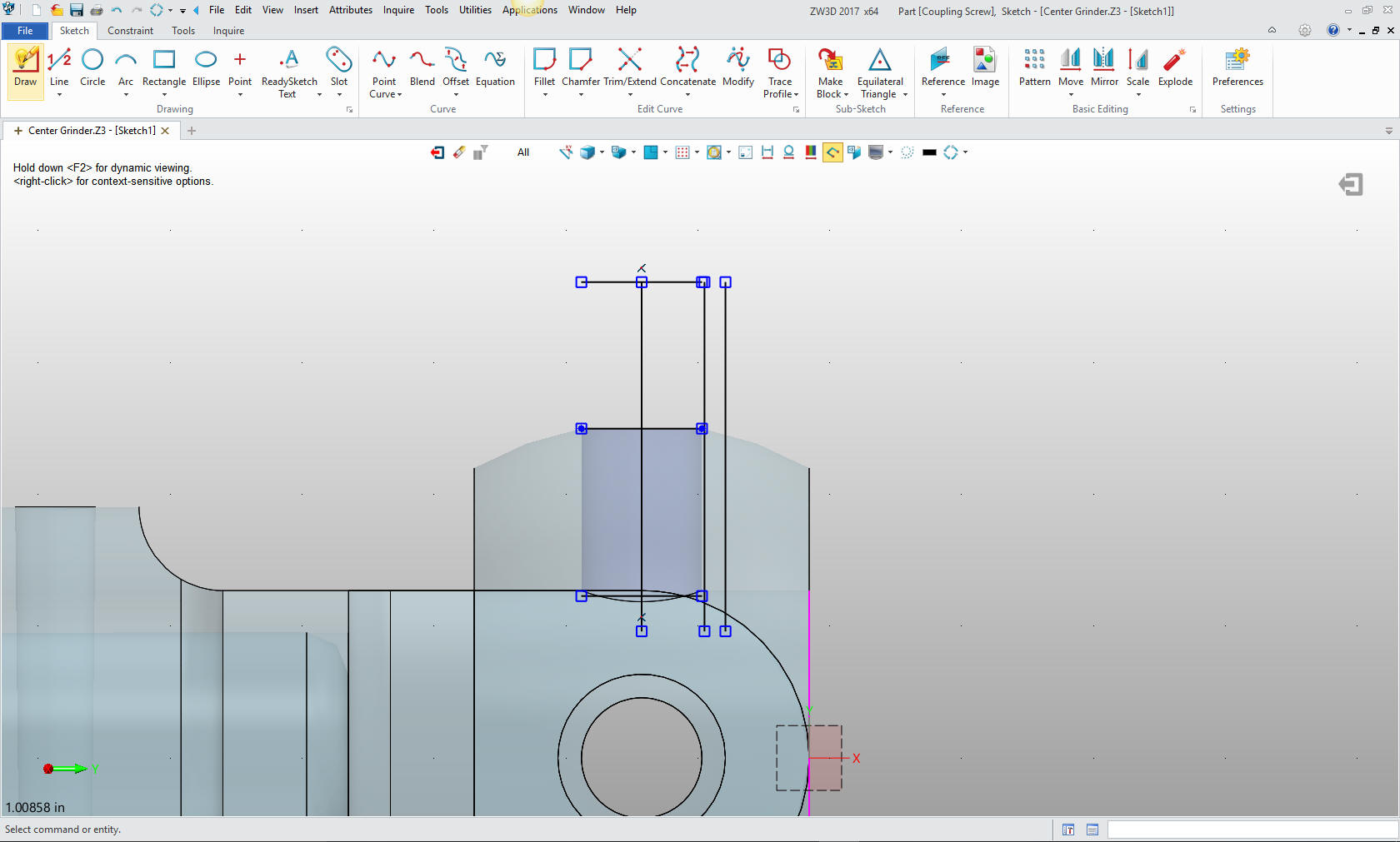

sketch the coupling screw for a revolve. Showing you when you design

in context you will evaluate which design process to use depending

on the supporting graphics or mating parts. There is no face to

insert the cylinders. I could create the head of the screw and

inserted cylinder, but speed is our focus.

Again I create

the sketch with offset lines, trimming, extending and deleting. All

3D CAD system allow for this type of sketching.

Final profile. The only reason I focus on this is that I have seen

how many of you were trained to sketch. That process was developed

in 1988 with introduction of Pro/e. It was very convolute and an

overkill for designing part. Wasting hours of time. As you designed

in Pro/e you would do it in such a way as to have the drawing almost

automatically detailed. Remember the purpose of 3D CAD prior to CNC

was to provided a drawing.

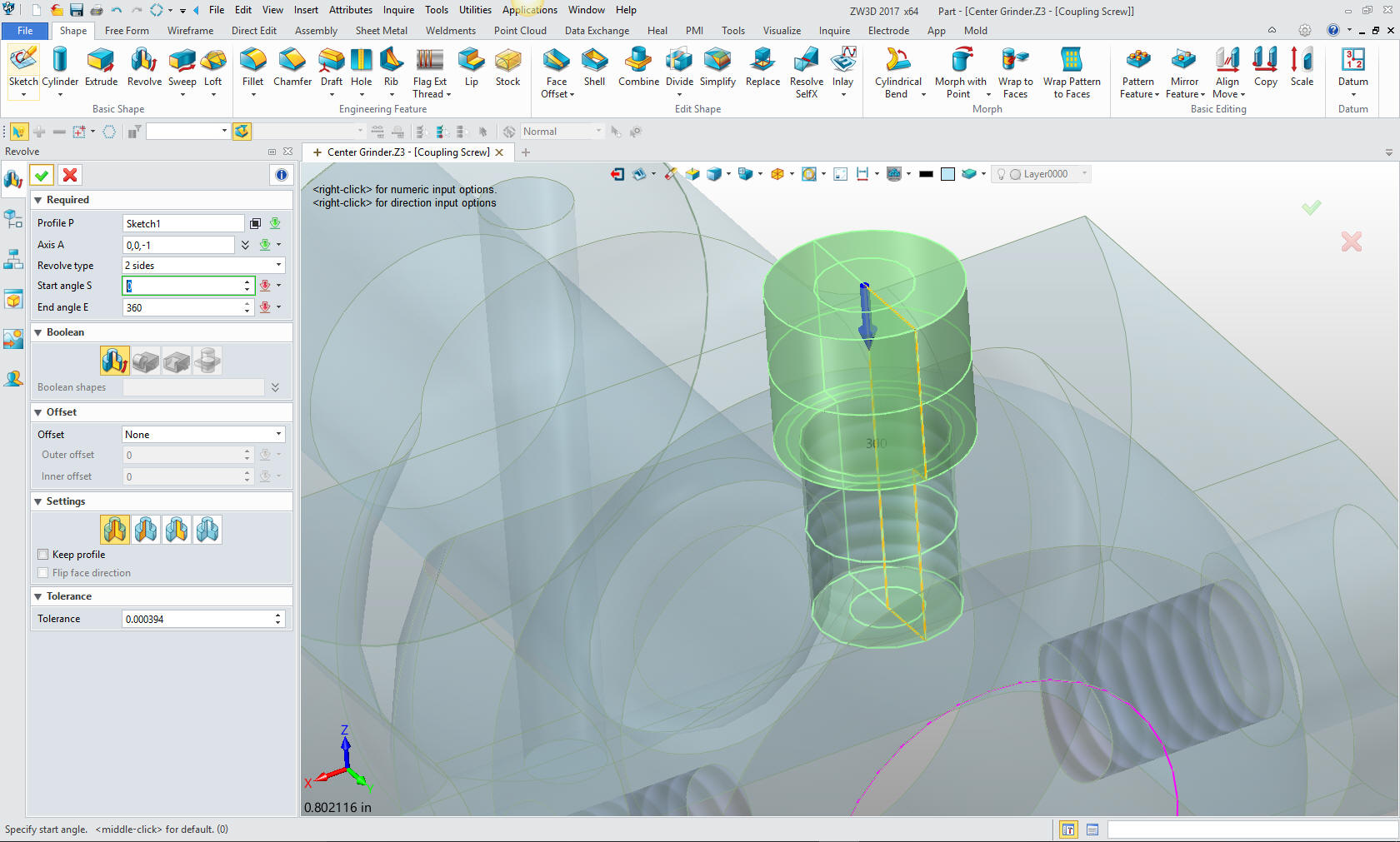

Revolve the profile.

Now

the slot on top by inserting a primitive block and sizeing

Now add the

threads and we are done with the screw.

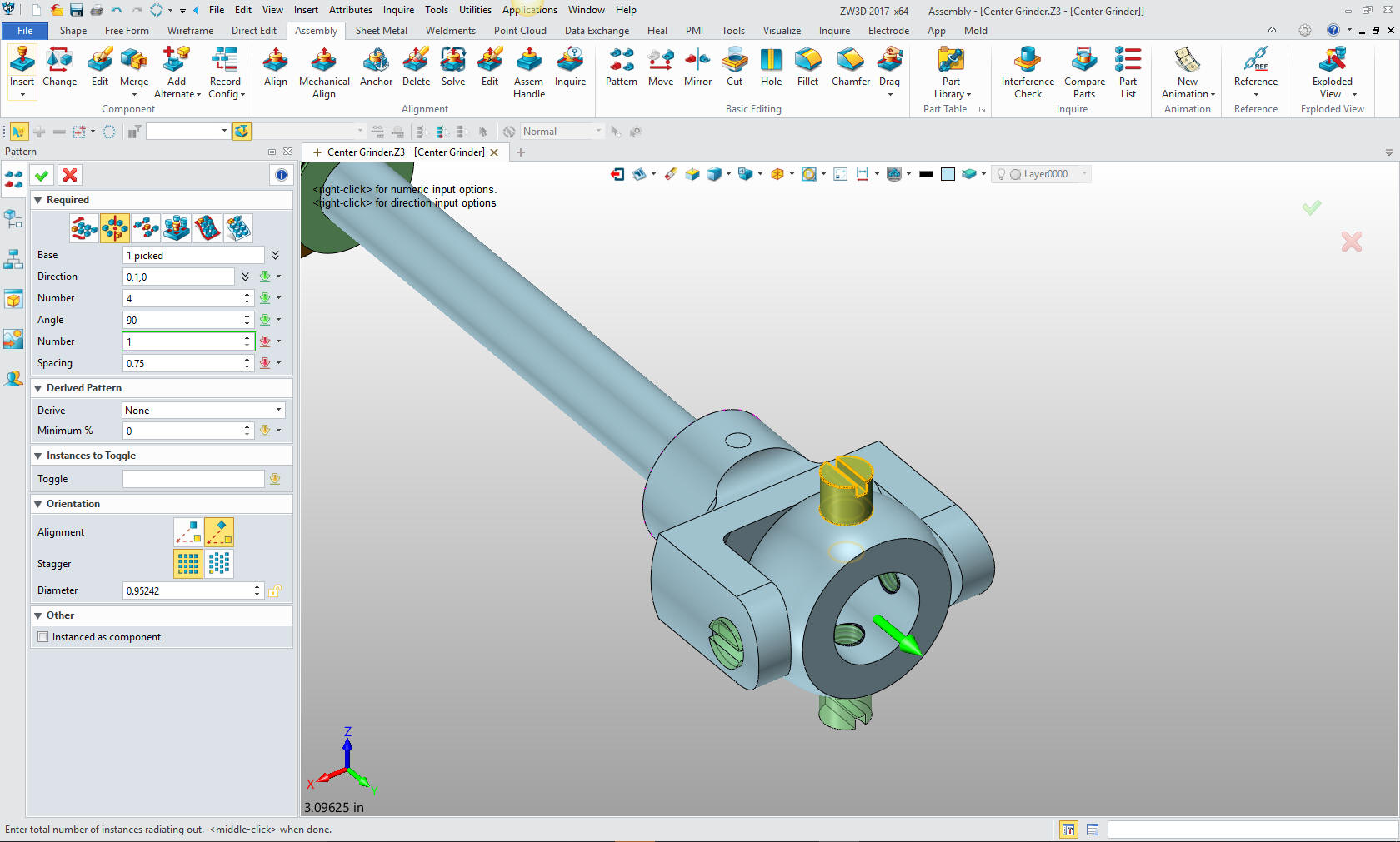

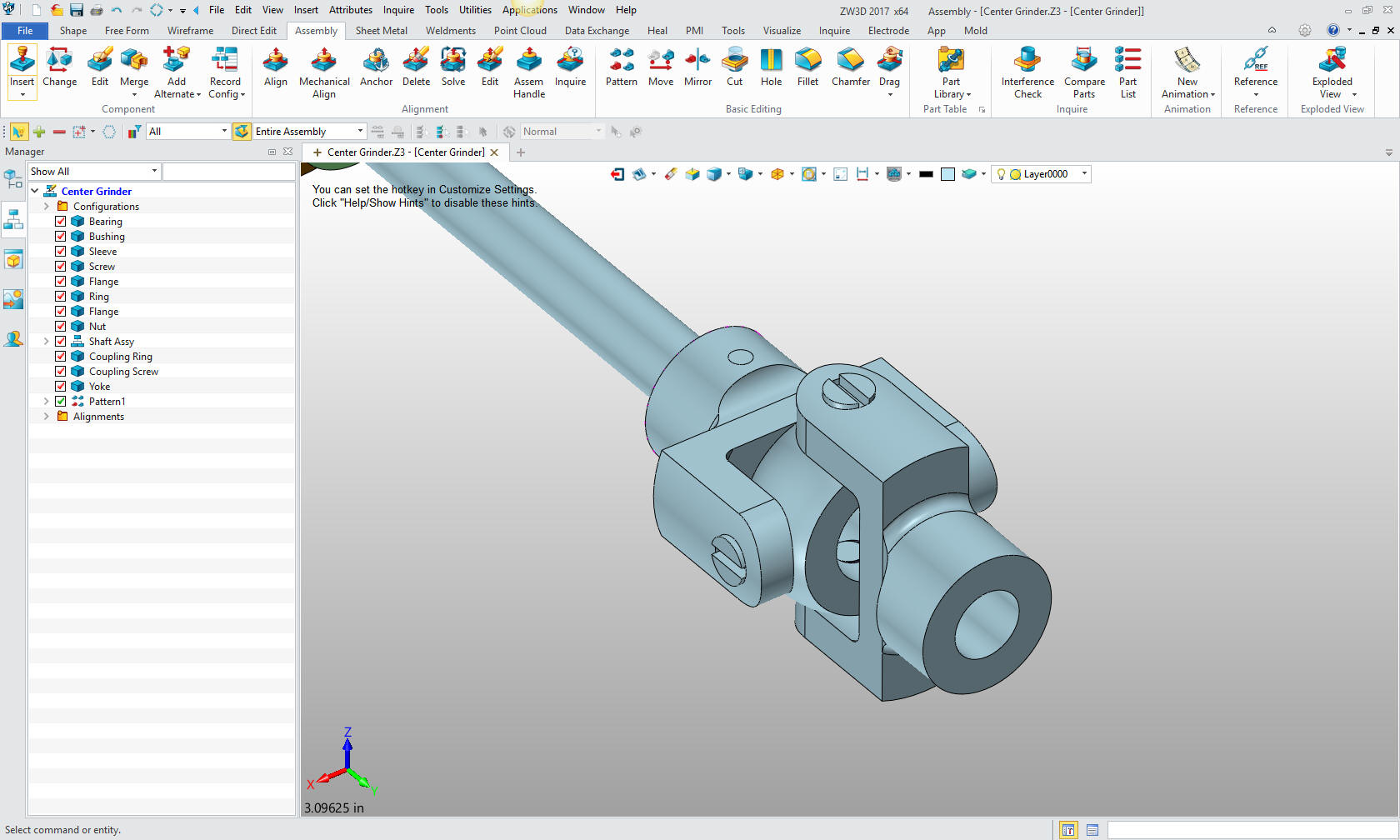

We

pattern the screws

We

need two yokes so we will insert a yoke in the top Grinder Center

assembly and locate it.

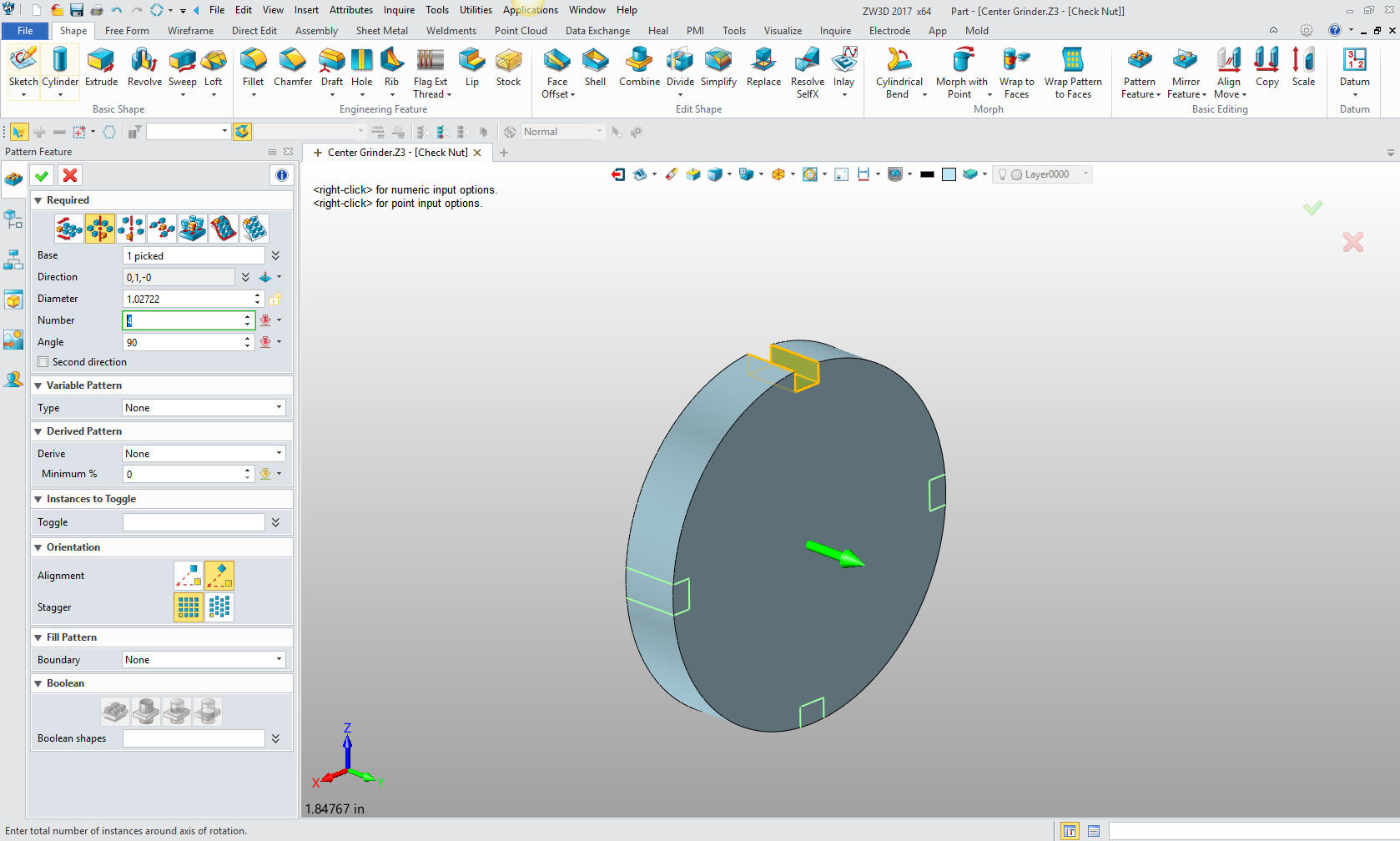

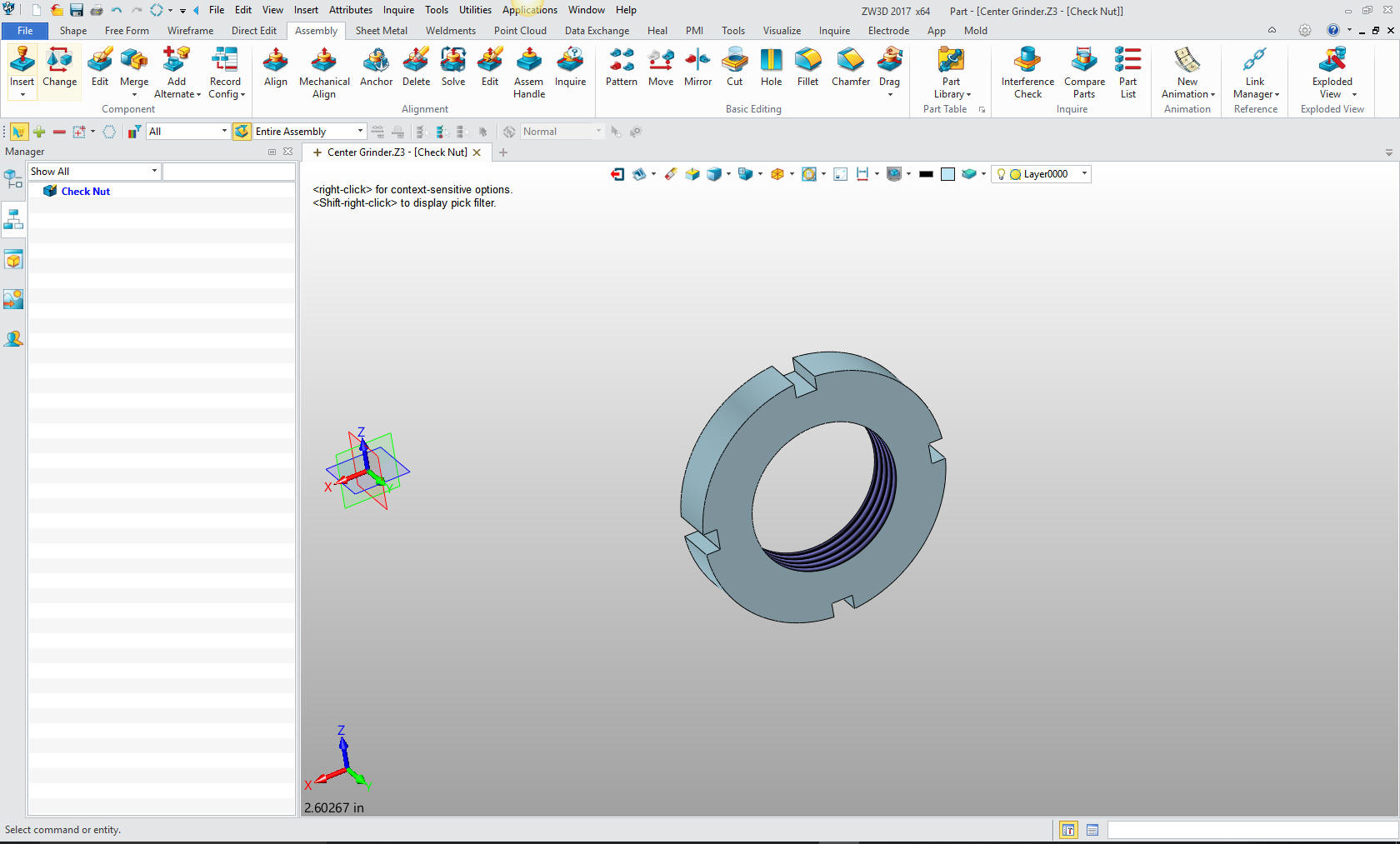

Whew,

we only have two parts left. Now for the check nut.

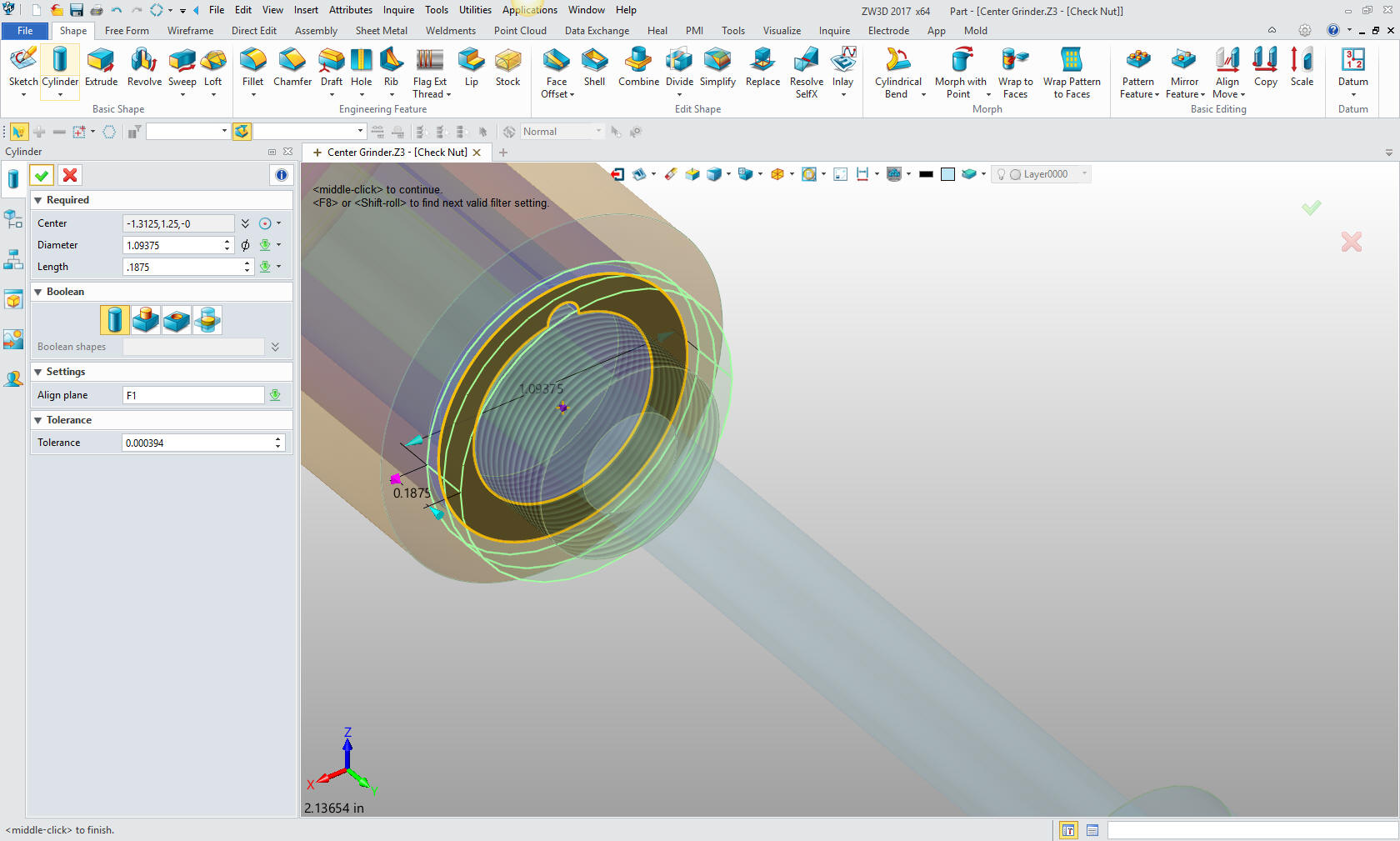

This

time I referenced a face so I could align my primitive cylinder. I

locate and size it.

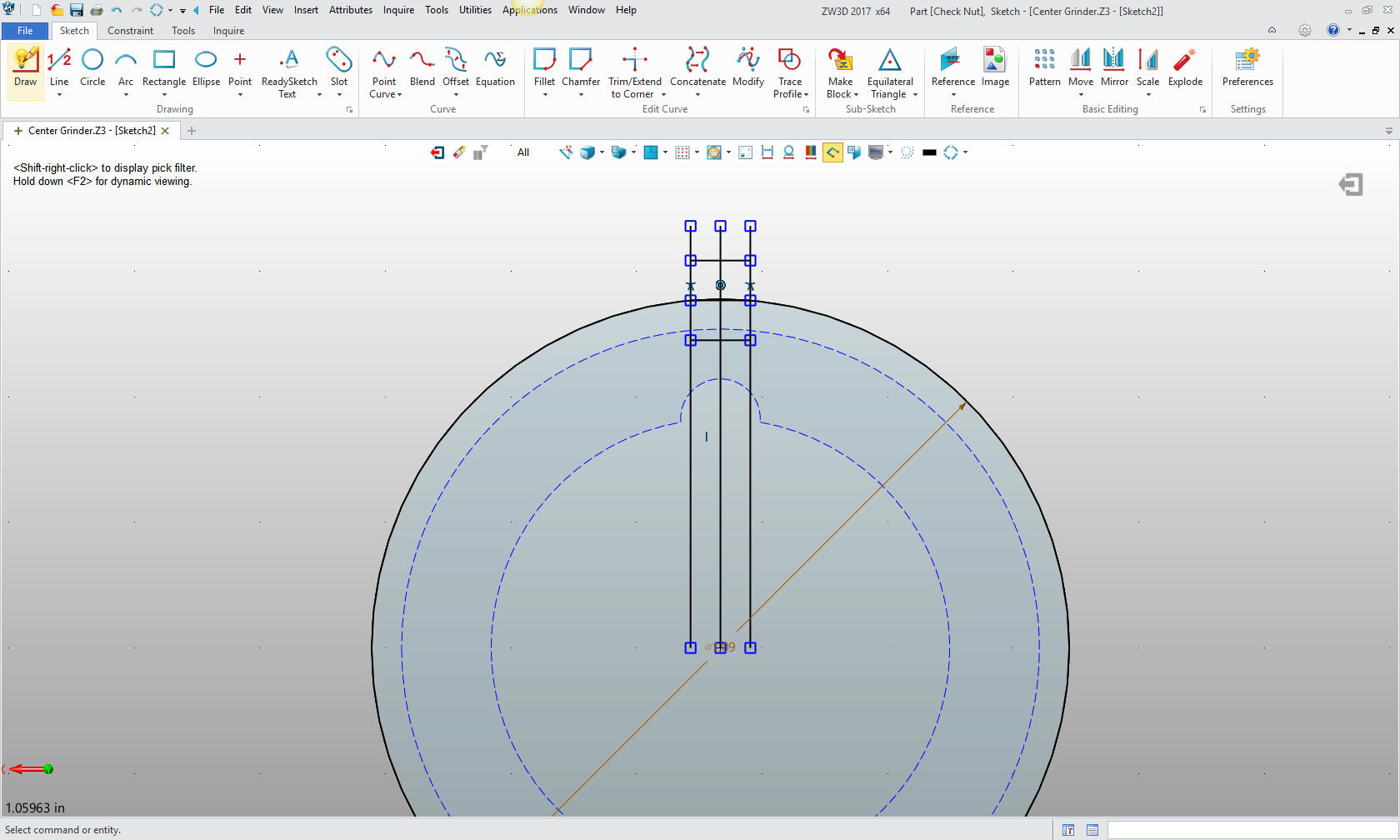

Now

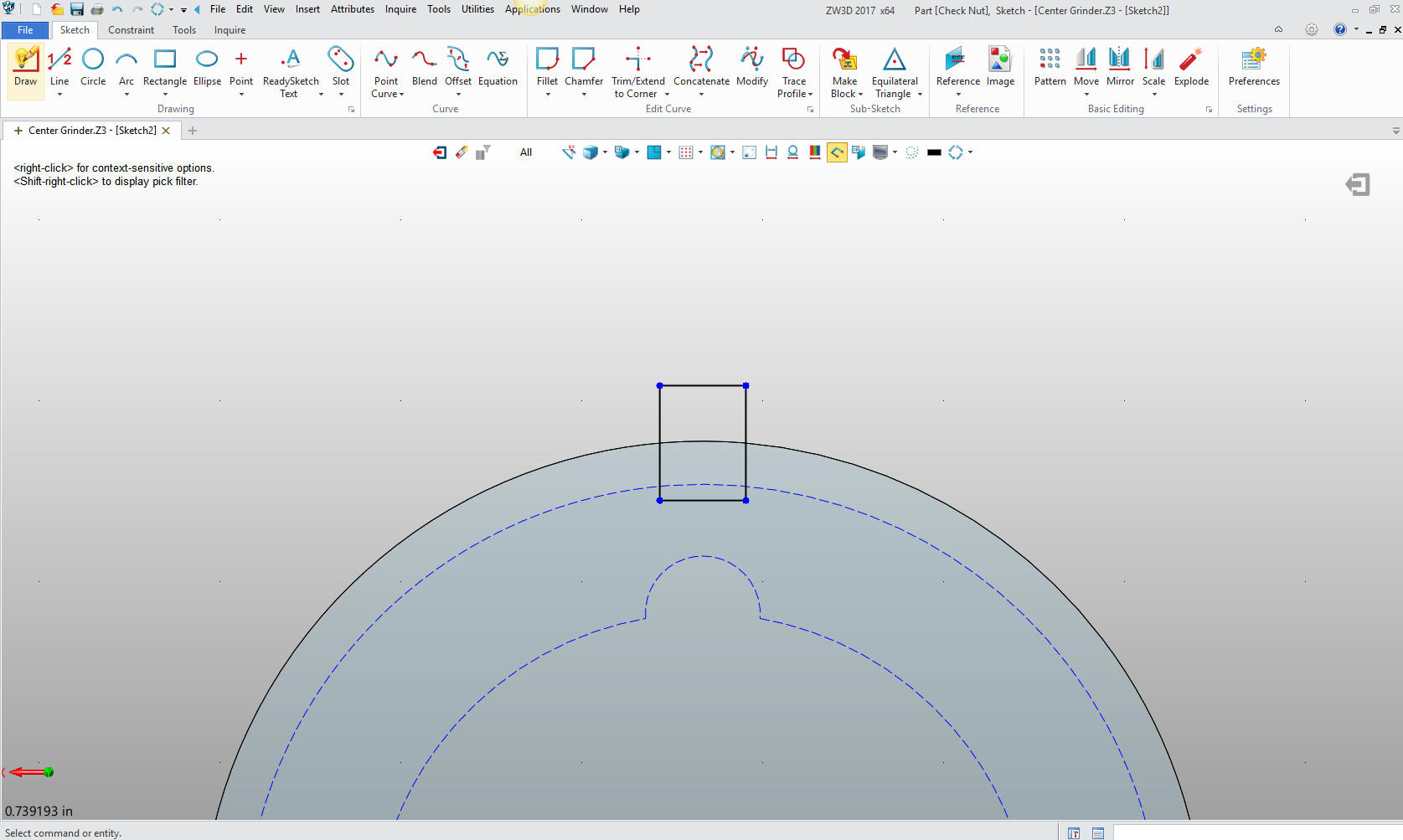

for the slots. Again I emphasize how I sketch. I created a vertical

line on the center, created a circle the size of the outer radius

and defined the lines and offset, trim, extend and delete.

Here

is the final profile.

We

extrude and pattern

Now

for the threaded hole and we are done.

There

are two check nuts so I will insert another and locate.

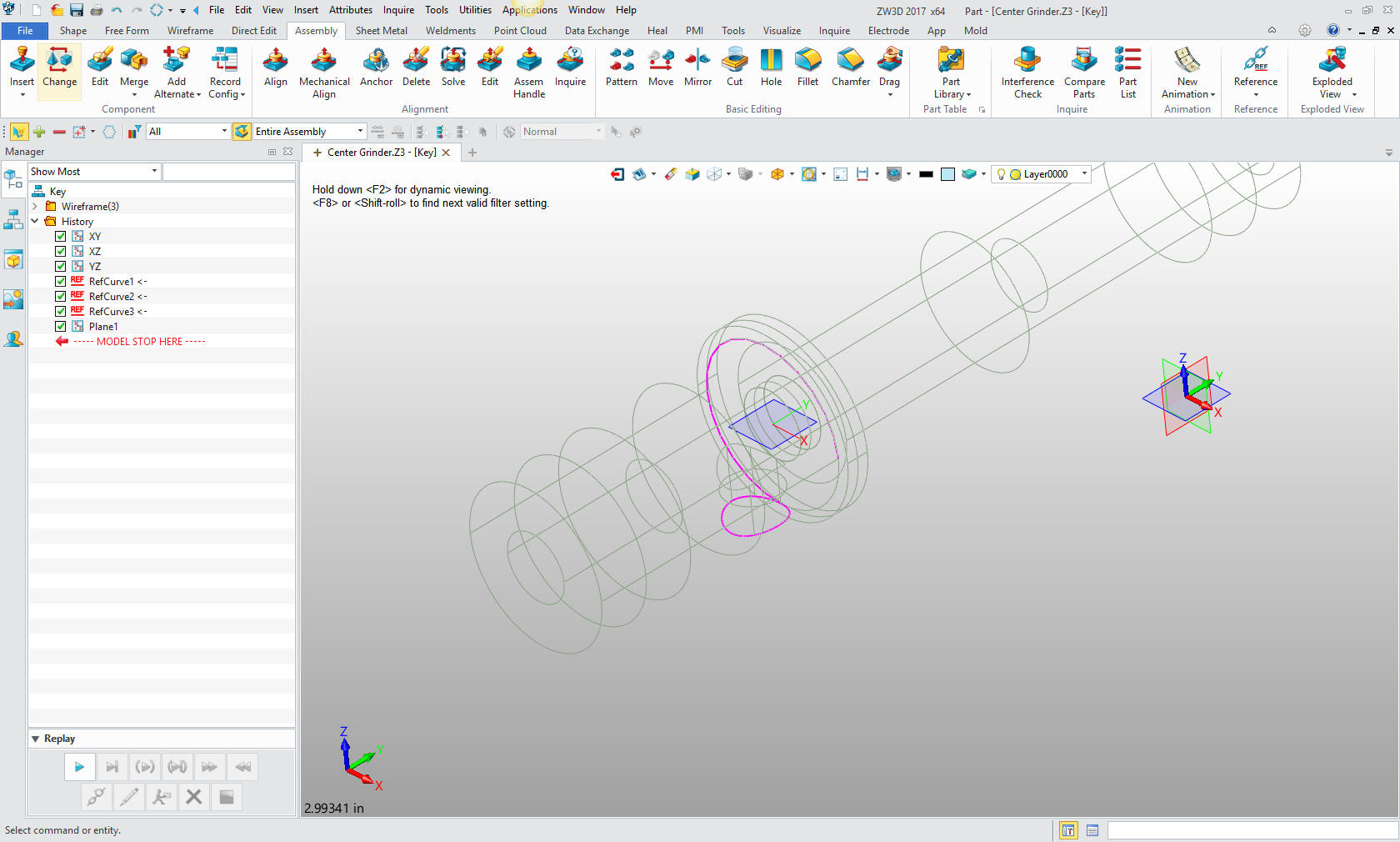

Now

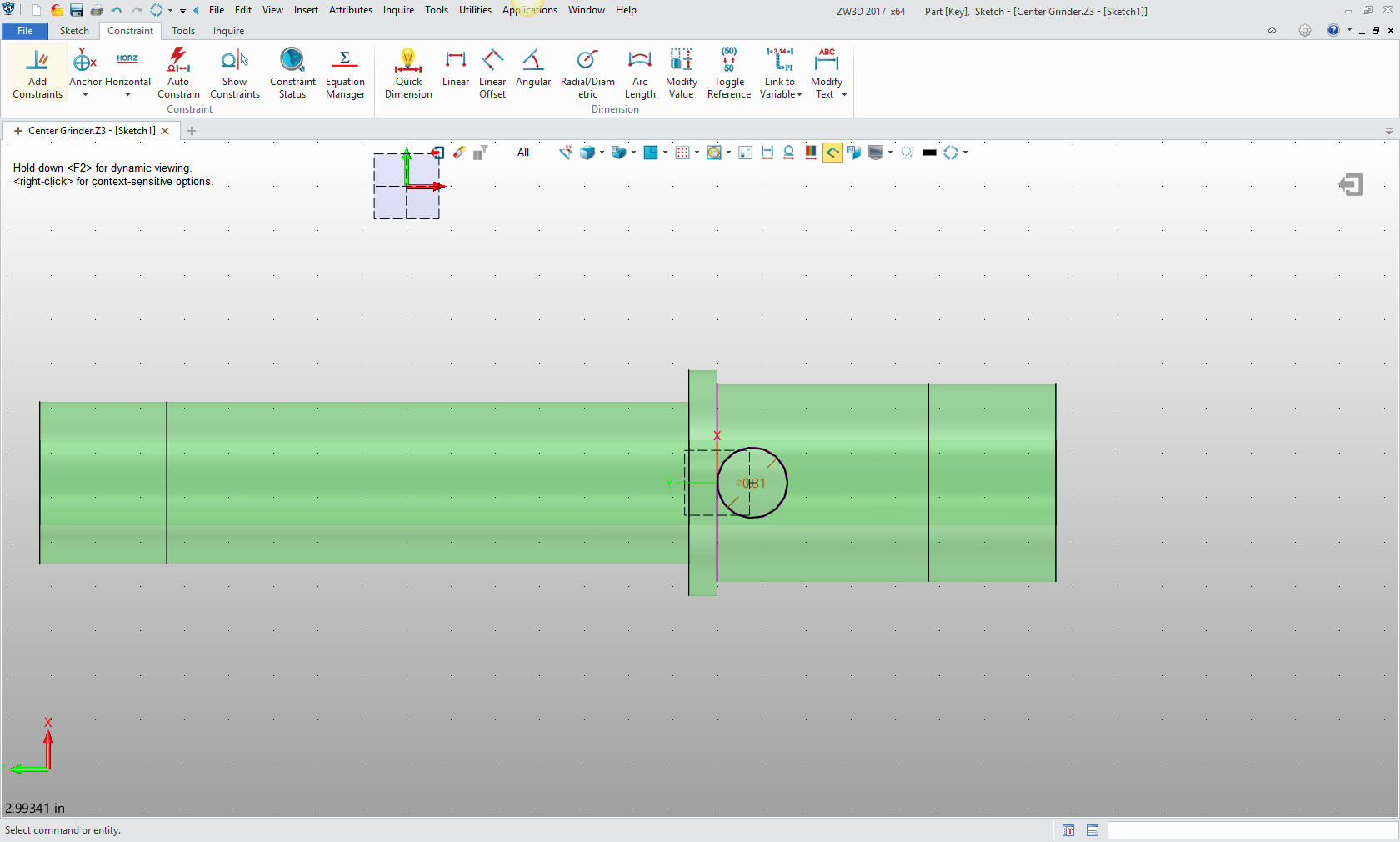

for the key. We create reference curved to use in the sketch. I

know, I know, a bit unconventional. But design in context is a bit

different. I am sure this is quite new to many of you. I am just

trying to show another way of modeling.

Now

to sketch the cylinder.

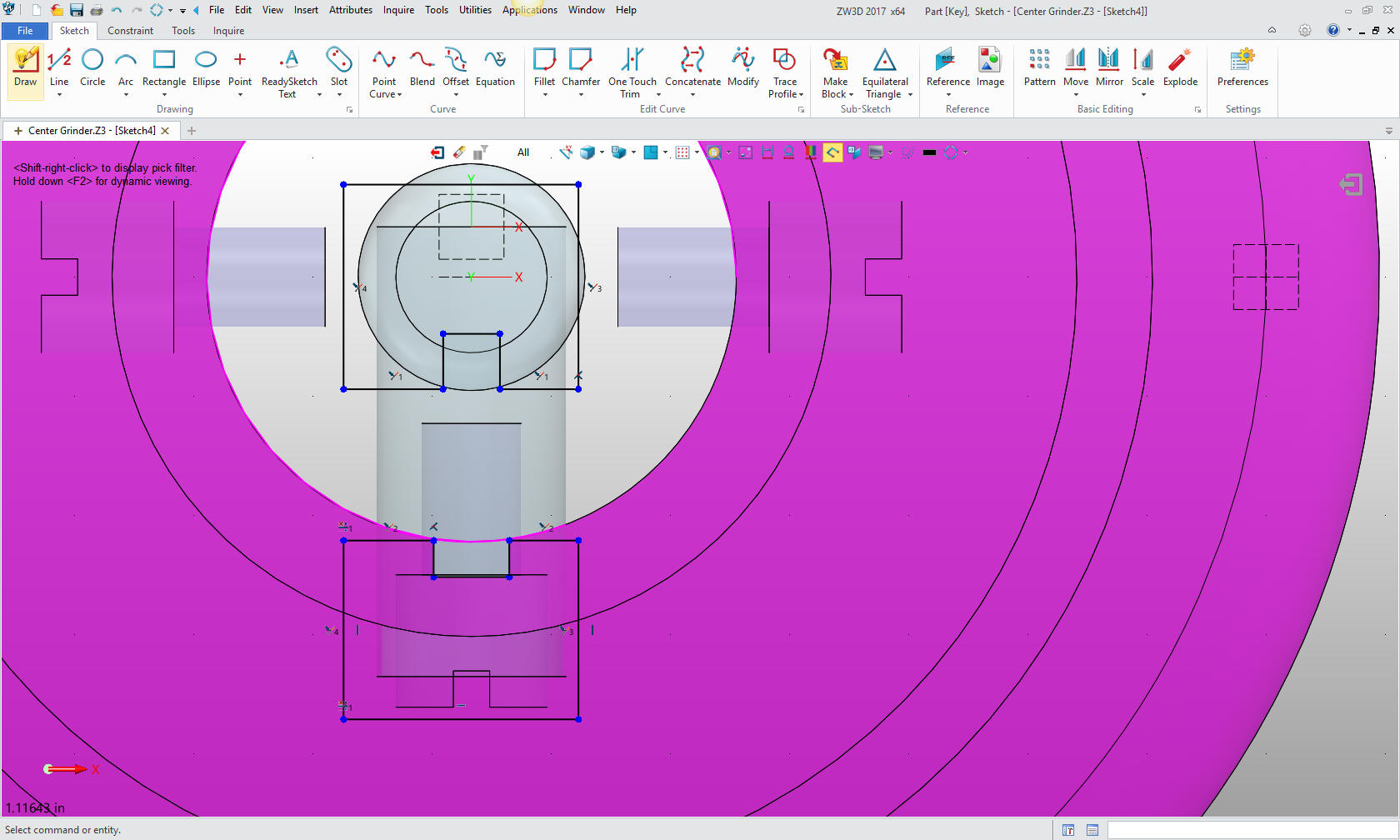

Now to

extrude, we will make it a bit over sized since we are going to use

the flange and shaft for reference for our next cut.

We

will now make the final sketch.

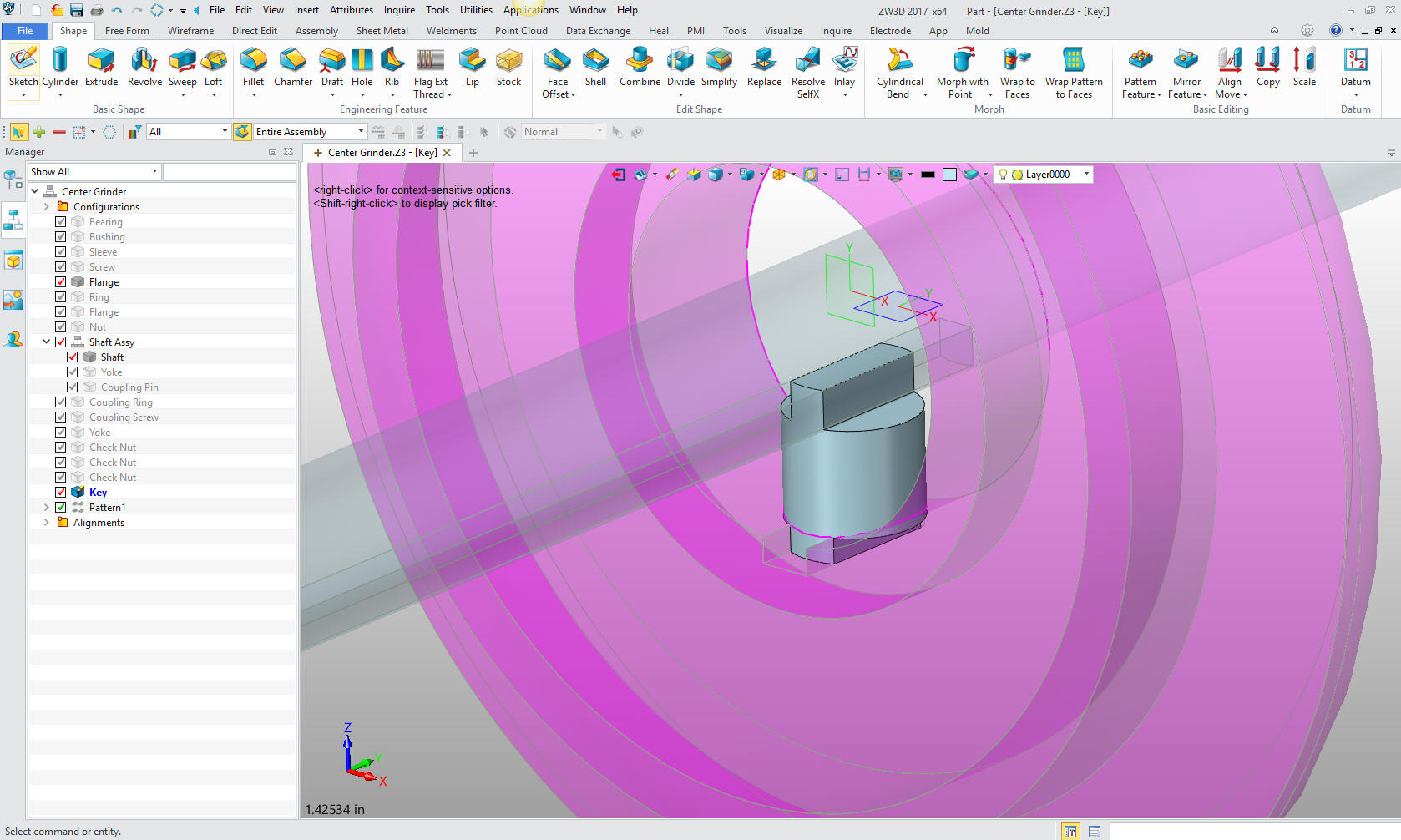

Now to

extrude and we are done with our parts.

Here

is the completed part to date.

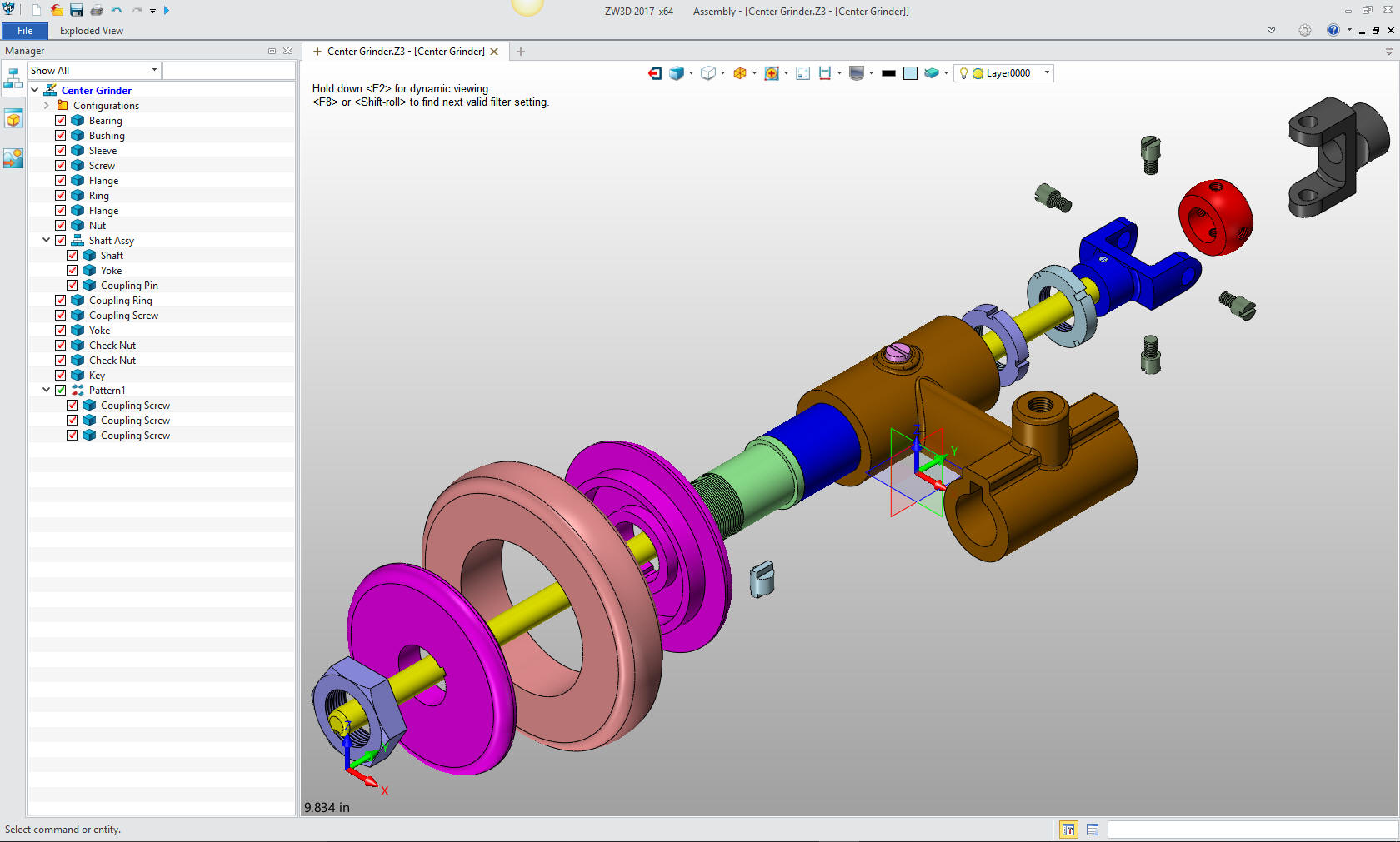

Here

is an exploded view, yes in one file.

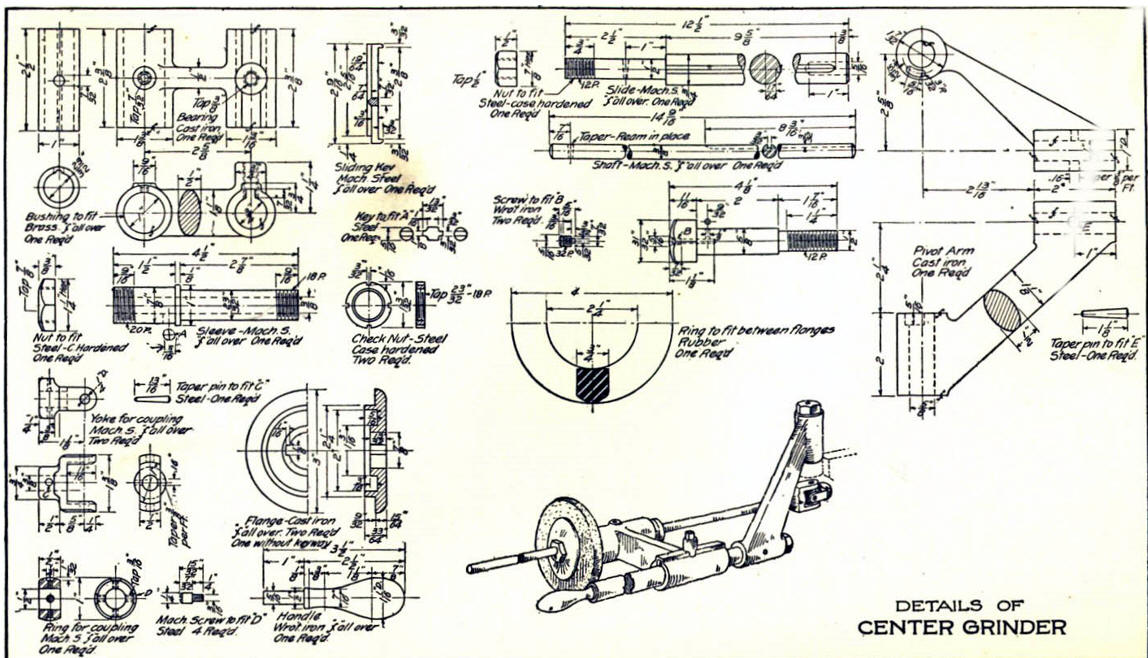

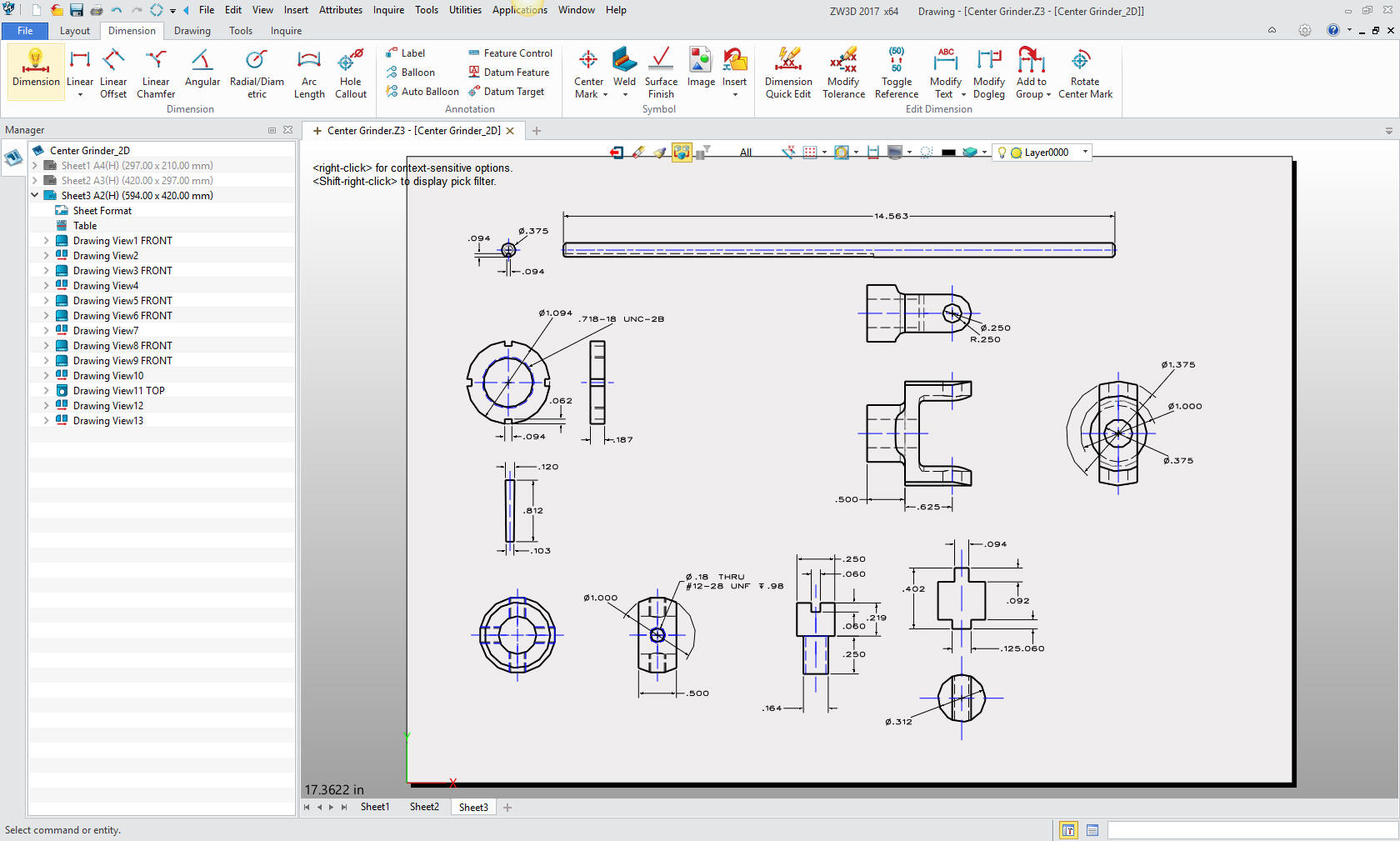

Here

are the views defined in the 2D sheet generated from the Center

Grinder assembly. We add the dimensions and we

are completely done with the part. Please remember, we have done

this all in one file. Think it through!

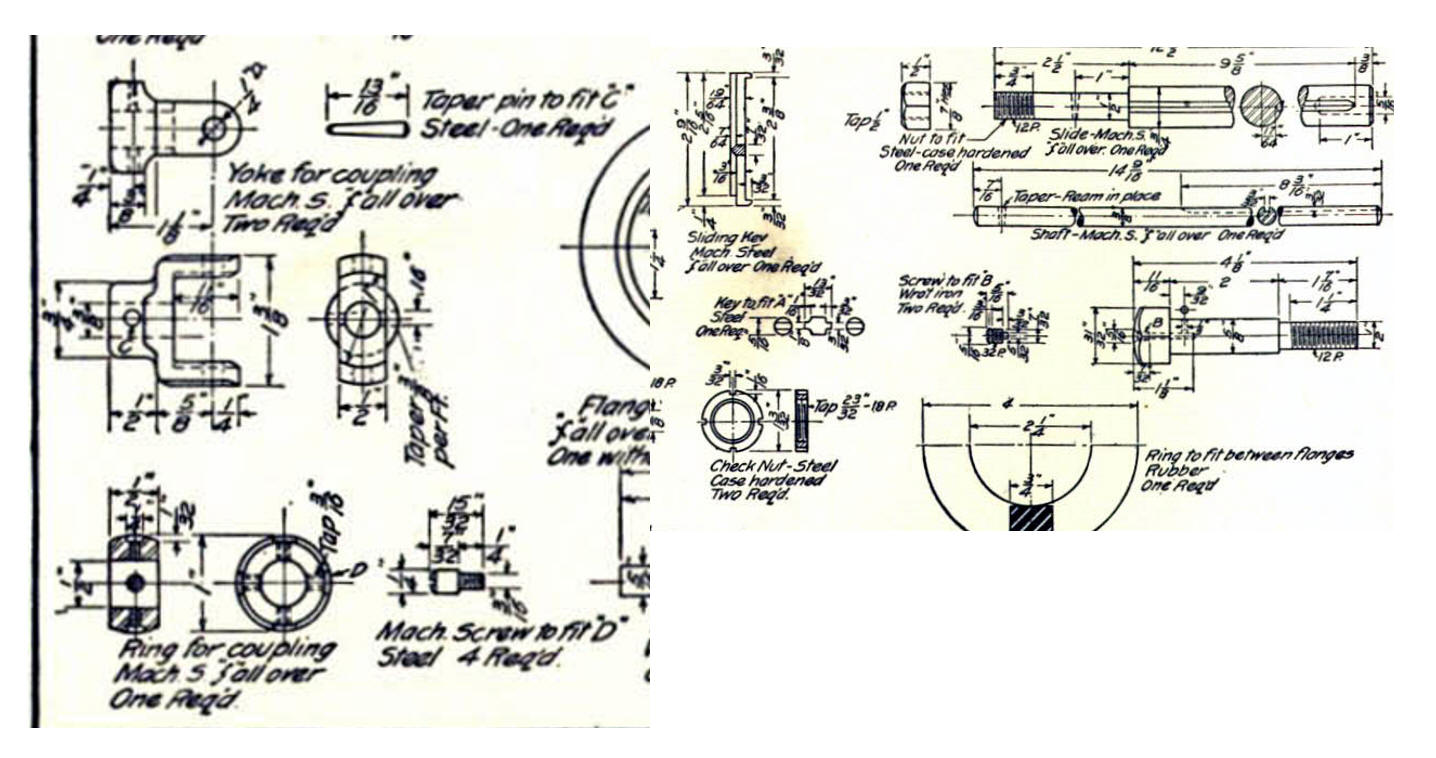

Here

is the original. I did add some dims that were not defined.

Now for lesson Five:

3D

Modeling Techniques ZW3D Lesson Five

If you would like

to try ZW3D, please download for a 30 day evaluation.

Download ZW3D

Give me a call if you have any

questions. I can set up a skype or go to meeting to show this part

or answer any of your questions on the operation of IronCAD. It

truly is the very best conceptual 3D CAD system.

TECH-NET Engineering Services!

We sell and

support IronCAD and ZW3D Products and

provide engineering

services throughout the USA and Canada!

Why TECH-NET Sells IronCAD and ZW3D

If you are interested in adding professional

hybrid modeling capabilities or looking for a new solution to

increase your productivity, take some time to download a fully

functional 30 day evaluation and play with these packages. Feel free

to give me a call if you have any questions or would like an on-line

presentation.

For more informationg or to download IronCAD or ZW3D

Joe Brouwer

206-842-0360

|

| |

|